Events > Tilt-Up Future Think 4.0 > SESSION

Session 3: Eco & Ethos

June 24, 2024 from 2:45pm to 4:30pm Central Standard Time

Edlis Neeson Theater

Cameron M. Trefry, NCARB, LEED AP

Erika Winters-Downey, S.E., LEED AP BD+C

This session tackles the dual challenges of environmental sustainability and workforce management within the construction industry. Discussions will range from innovative low-carbon concrete solutions and the implications of evolving VOC regulations to strategic responses to labor shortages. Learn how integrating environmental considerations with positive workplace initiatives is essential for the industry’s sustainable future.

Low-Carbon Concrete Mix Design for Schedule-Driven Tilt-Wall Construction: Tilt-wall construction is typically schedule-driven; the use of high early-strength concrete mixes to facilitate “tilting” or erecting of the wall panels within an aggressive construction schedule is often necessary. Wall panels are typically tilted 5-7 days after pouring, but sometimes as early as three days. Conversely, the use of Supplemental Cementitious Materials (SCMs) in low-carbon concrete mix design can extend traditional strength gain curves of Portland cement mixes. In 2023, Clayco and Concrete Strategies partnered with Wiss Janney Elstner engineers, Ozinga ready-mix, Breakthrough Energy and Climate Works foundations to test, pour and tilt three tilt walls with varying levels of carbon reduction. The test was performed in aggressive winter conditions, forming a baseline for worst-case strength gain for many mixes. This session will discuss the mixes tested, laboratory and field results, feedback from crews with regards to pumping and finishing the mixes and plans for next steps.

Chemical Change - VOCs Reshaping Tilt-Up's Mix: The construction industry is experiencing a rapid influx of innovation driven by advancements across various technologies. Sustainability is a growing priority, with the United States and the global community striving for environmentally responsible practices. This focus presents both challenges and opportunities for the tilt-up concrete industry. This presentation will explore how evolving concrete mix designs and VOC regulations are impacting the chemicals used in tilt-up construction, including bondbreakers, densifiers, curing compounds, and more. The discussion will also examine the current landscape and what the future holds for these essential products.

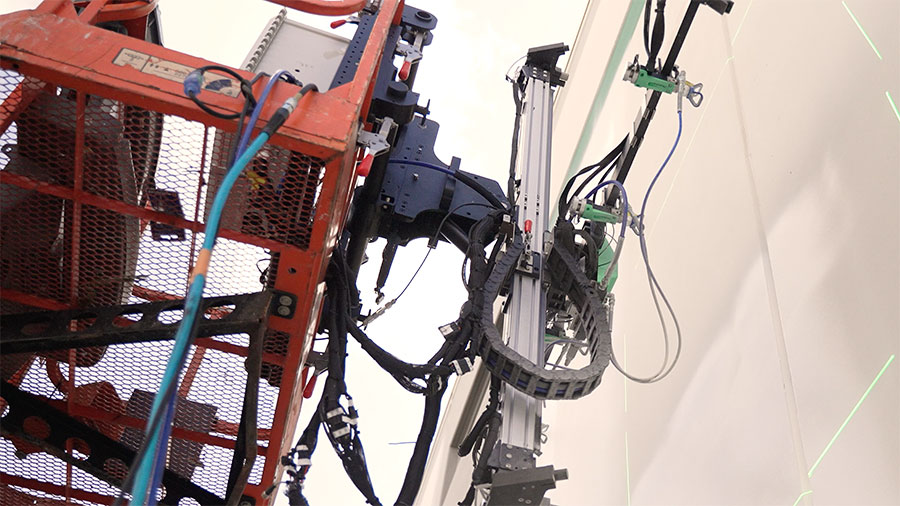

Evolving Energy Codes: As energy codes continue to evolve with a focus on increased thermal and vapor performance for walls, roofs, and building fenestration, the tilt-up concrete industry must also evolve. Will the market acceptance of building interior-mounted insulation increase as R-values and insulation thicknesses increase? Is sandwich panel construction a cost-effective alternative? We will discuss the incoming 2024 IECC standards and beyond as they relate to tilt-up concrete construction. How can the industry evolve to maintain and continue to improve its position as a dominant structural and building envelope solution?

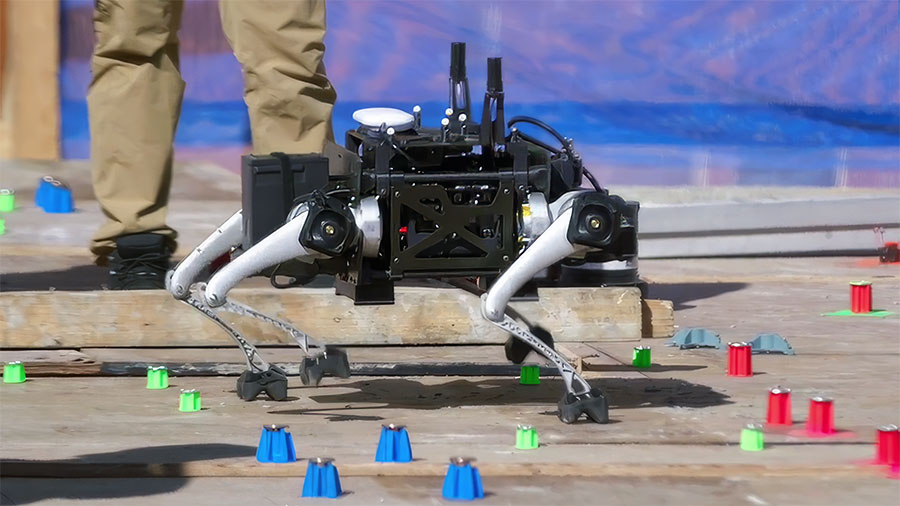

How Alignment of Incentives Can Address Construction Labor Shortages: The construction industry grapples with a substantial labor shortage exacerbated by demographic shifts, with projections indicating over 1 million unfilled positions by 2025 and 2 million by 2030. Addressing this challenge necessitates a multifaceted approach involving enhanced recruitment/training, systematic process improvements, and increased worker productivity. Protiv's focus lies particularly in revolutionizing labor compensation structures, aiming to align management and field staff incentives, fostering quality, teamwork, safety, communication, and productivity over mere hours worked. Implementing this approach yields an average productivity boost of 15%, alleviating labor shortages and enabling contractors to maximize workforce capacity.