UDOT Milford Maintenance Complex

Summarize the project's program, features and achievements.

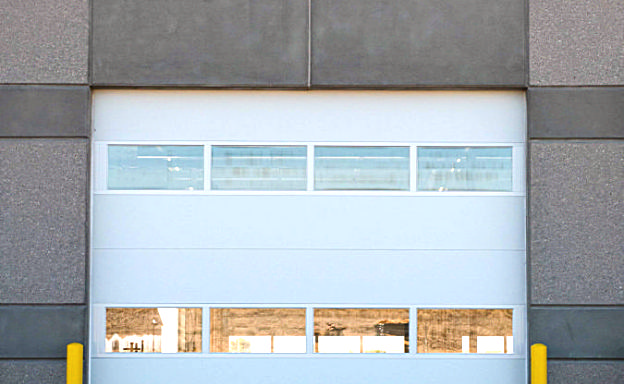

The Utah Department of Transportation has many maintenance facilities throughout the state built with much different construction types-except tilt-up. Our team won the design-build project for the remote site of the Milford UDOT Maintenance Complex and delivered a better value than any of their previous maintenance facilities. The project combined previous designs of multiple outbuildings into one multifaceted building. The project included the maintenance building, salt storage building, brine storage tanks, and wash rack to create a consolidated building to add simplicity, site circulation, and significantly lower the cost of construction. The maintenance building was designed and constructed to need little to no maintenance in the future. The facility features pull-through bays, architectural exposed concrete sandwich panels, an internal wash bay, multiple areas for long-term storage, and MagicSlab TM concrete floors throughout the shop areas, restroom and office areas. The facilities' design was intended for use on future UDOT sites as it is configurable for any site regardless of size, location, or budget. To reduce the size of the site, the design eliminates the need for outside storage by adding the salt storage as a bay instead of a separate building and adds a concrete storage room underneath the brine tank pedestals as part of the larger building. Even further, the design eliminates the need for evaporation ponds that were used in previous UDOT sites by processing all of the water from the conditioned wash bay instead of an outside wash rack through the local sewer district instead of draining to the ponds.

What obstacles were overcome related to the schedule, budget, program, specification, site, etc. on this project?

In the past UDOT maintenance facilities were typically constructed using a masonry design under the CM/GC delivery method. The Milford UDOT project had a particularly small site and required a different approach. Hughes and JRCA worked together, using a design/build delivery, to design a facility that was both cost effective, collaborative, and durable. Selecting tilt-up over masonry helped the project stay on schedule and offered the added benefit of being a nearly maintenance-free building. Hughes used their in-house tilt-up expertise in designing and budgeting the Milford project. Their system helped ensure the design and budget met the client's financial needs.

Communicate any engineering complexities or unique features of the panel design for this project.

The Milford UDOT Maintenance Facility's design is a departure from some of the current UDOT maintenance facility design approaches that utilize masonry. Milford's tilt-up concrete panels are insulation sandwich panels that provide durable inside and outside surfaces for the entire structure. These insulated panels are a practical solution to the on-going issue of providing an energy-efficient layer to both interior and exterior surfaces to keep the heat and cold in as well as to keep the heat and cold out. The exposed panels also play a dual function; they are durable on both sides and were specifically designed to reduce the need for heavily reinforced walls that are required for pushing stored salt. The tilt-up panels provide add texture and color to the finished facility. Rather than have the vehicle cleaning bays located on the building's exterior, as with other UDOT maintenance facilities, Milford's bays are located inside to better control the salt residue that would otherwise be left to drain into storm water or open pond run-off channels. This interior bay design aims to provide a long-term solution to care for the local environment.

What is the potential for this project's impact on the community and/or environment?

The facilities' design was intended for use on future UDOT sites as it is configurable for any site regardless of size, location, or budget. To reduce the size of the site, the design eliminates the need for outside storage by adding the salt storage as a bay instead of a separate building and adds a concrete storage room underneath the brine tank pedestals as part of the larger building. Even further, the design eliminates the need for evaporation ponds that were used in previous UDOT sites by processing all of the water from the conditioned wash bay instead of an outside wash rack through the local sewer district instead of draining to the ponds.

Project Location

Milford, UT 84751

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2022

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Hughes General Contractors, Inc.

- Concrete Contractor:

- Architect:

- Engineer:

- BHB Consulting Engineers PC

- Suppliers:

- Photographer(s):

Project Specifics

- Project Category:

- Transportation

- Building Types:

- Transportation Hub

- Finishes:

- Concrete (Exposed Aggregate)

- Features:

- Insulation:

- Sandwich Panel (Non-Composite)

- Environmental:

- Number of Floors:

- 2

- Number of Panels:

- 45 panels

- Tilt-Up Wall Area:

- 14,786 sq ft (1,374 sq m)

- Total Floor Area:

- 13,200 sq ft (1,226 sq m)

- Project Footprint:

- 17,622 sq ft (1,637 sq m)

- Tallest Panel:

- 28 ft 3 in (8.61 m)

- Widest Panel:

- 39 ft 11 in (12.17 m)

- Largest Panel:

- 784 sq ft (72.8 sq m)

- Heaviest Panel:

- 98,962 lbs (44,888 kg)