KHL Office Warehouse

Summarize the project's program, features and achievements.

Our goal for this building was to be able to showcase several unique aspects of Tilt-Up Construction. of few of these include insulated sandwich panels, 3D feature walls, form liners, exposed concrete exteriors. in addition to this the insulated sandwich panels allowed us to explore some unique finishes for the inside of our building. as part of the finishing processes of the panels we broadcast silica sand on the surface of the panel and applied a chemical retarder. this provided a uniform exposed aggregate finish inside our office. we were also able to polish panel before they were stood to achieve a clean smooth finish. we decided to leave the pick and brace points exposed inside the office as a way to demonstrate and explain the means and methods and standing the building. To insure a smooth uniform finish on the outside of the panels we used a self compacting concrete (SCC) in the outer Wyeth.

What obstacles were overcome related to the schedule, budget, program, specification, site, etc. on this project?

with the interior of the panels being exposed in the office we had to work closely with our MEP trades to insure we had correct placement of conduits for outlets, switches, and the like. with only having crane access on one side of the building we have to strategically size the panels on the far side of the building so the crane was apple to reach cross the width of it and set them panels. being that our panels were all going to be exposed we could not stake them so we had to cast several casting slabs onsite to ensure a flawless finish.

Communicate any engineering complexities or unique features of the panel design for this project.

we decided to go with a three dimension feature panels on the corner of our building. These panels very from 13.5" thick to 24" thick. to do this we created a massive void form that had a layer of foam, then stucco, then we coated the entire surface with epoxy to produce a smooth casting surface. With a lot of this mass of the panels being on the outside of the sandwich panels we had to take special care in placing the pins for the insulation to make sure the face did not pull off of the foam. To prevent the thin outer Wyeth of concrete from cracking we incorporated Macro-fibers in the concrete.

What is the potential for this project's impact on the community and/or environment?

our 3d feature panel is extremally unique and identifiable. since completion of the building we have had several suppliers, contractors, and individuals buzzing about it. We look forward to incorporating additional unique features on our next building.

Project Location

West Jordan, UT 84088

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2022

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

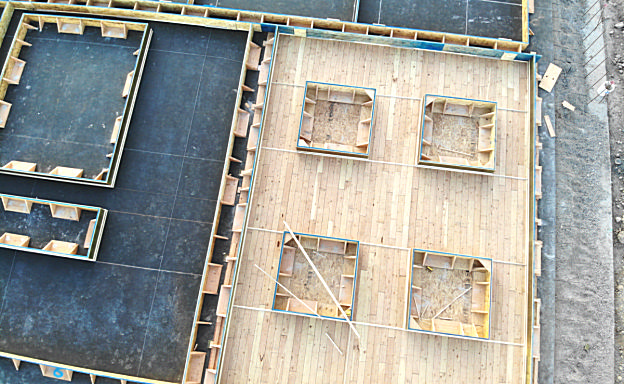

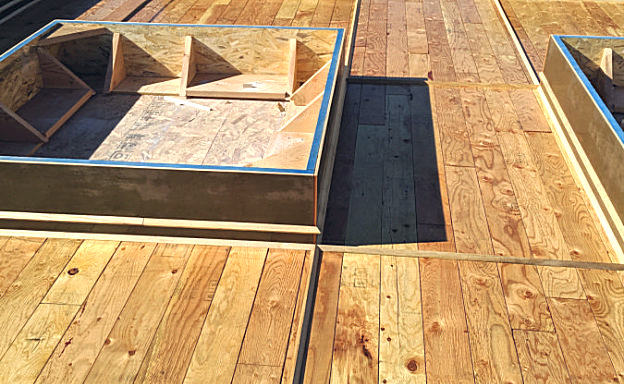

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- KH Love Construction

- Concrete Contractor:

- Architect:

- Engineer:

- Suppliers:

- Photographer(s):

Project Specifics

- Project Category:

- Office

- Building Types:

- Office

- Warehouse

- Finishes:

- Features:

- Voids

- Insulation:

- Sandwich Panel (Non-Composite)

- Environmental:

- Number of Floors:

- 2

- Number of Panels:

- 43 panels

- Tilt-Up Wall Area:

- 13,200 sq ft (1,226 sq m)

- Total Floor Area:

- 12,500 sq ft (1,161 sq m)

- Project Footprint:

- 10,500 sq ft (975 sq m)

- Tallest Panel:

- 32 ft 10 in (10.01 m)

- Largest Panel:

- 685 sq ft (63.6 sq m)

- Heaviest Panel:

- 93,800 lbs (42,547 kg)