Chroma

Summarize the project's program, features and achievements.

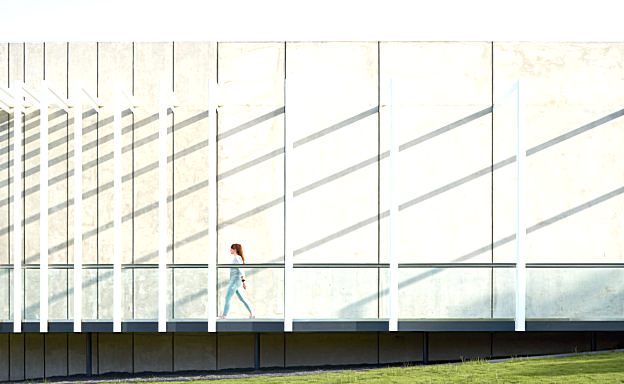

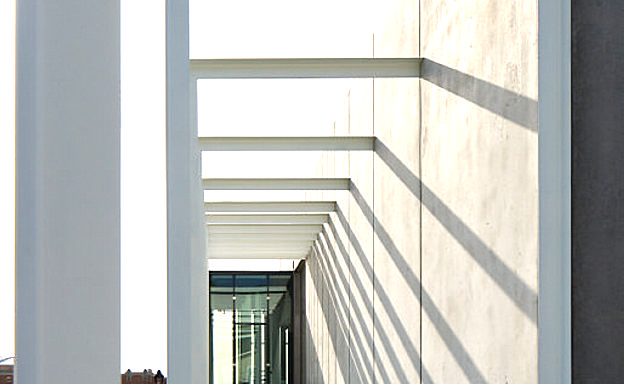

The 5600 SF Chroma modern eyewear and eyecare is placed along Montgomery Street adjacent to the Fort Worth Cultural District that includes museums by Louis Khan, Tadoa Ando, Renzo Piano, and Legoretta +Legoretta. This site is immediately across the street from, a new 14,000 seat multipurpose venue. The concrete structure on the west side of the building houses the optometry testing and exam rooms, spaces which require restricted daylight. Other interior spaces were designed to open up to daylight wherever possible. A void in the building form allows light in the office spaces. The admin space has a skylight bringing daylight from above. The optical sales and waiting area are set in a glass box that extends from the concrete form imagined as a piece of art protected by a clear enclosure. The sculptural interior is on display and invigorated with color every night. The meandering displays allow an exploration and expanded viewing of an array of frames. The structure of each display channels a shaft of light, literally illuminating the experience to the thousands of visitors approaching and departing the arena. The support shafts for the display are 6x6 steel angles. The same geometry appears in the glass curtainwall, and reveals itself in open frames along the elevated walkway, a gradual immersion into the experience as one approaches the building. This iconic building was completed for approximately $285/SF. Tilt-up concrete panels made this possible. The concrete panels are used structurally with steel and glue-laminated beams free-spanning between panels. Window openings were kept to a minimum on the west portion of the building which houses the optometry testing and exam rooms, spaces which require restricted daylight. All concrete panels were cast on site on casting beds. The panels have an unaltered natural finish with no chamfer to retain the purist qualities of the concrete, echoing the iconic concrete architecture of the museums in the adjacent district. The grade beam along Montgomery was cast with a mix and form system designed to mimic the panel finish. Unlike a typical tilt-wall building, the slab was cast after all panels and structure was in place to eliminate any column base or perimeter cold joints. All transaction desks and retail fixtures, including the acrylic displays boxes were designed by the architect for this project were made locally. Junction boxes embedded into the back side of the concrete panel to allow the acrylic boxes with integrated lighting appear as if they were attached to the face of the wall. The vertical shelf displays were made with bent steel plate and round glass shelves. To reduce the cost of the materials and fabrication the shelves were sourced from mass produced glass trivets. Simple steel fabrications and solid surfaces were used for the counters and desks. The floors are polished concrete and the signage is all simple powder coated aluminum plate.

What obstacles were overcome related to the schedule, budget, program, specification, site, etc. on this project?

Chroma is a building designed and built to a budget. The directive was to design a 6,000 SF optometrist office and retail space for $285/ SF on 4 city lots. The project was delivered at 5,600 SF on 3 lots for $285/square foot, including the retail fixtures and key custom interior furnishings. The methods of construction are wielded as the core design elements. This creates an intentional purity of form, material and function resulting in a wholistic design experience and the key to its fundamental economic austerity. Tilt-up concrete panels, performing the work of the grade beam, exterior wall, and vertical structure was essential to making the budget work. Care was taken in the details and finish of the panels to elevate the aesthetic value of the project. These concrete panels were exposed on portions of the interior. One panel was cast with 36 junction boxes to integrate a wall of acrylic cubes as a featured retail wall. Creative and direct sourcing of materials, and working with local fabricators made the creation of these custom elements possible. One example is the myriad of circular glass shelves needed for the project. After looking at many alternatives the design was modified to make use of "off-the-shelf" glass trivets, this resulted in a massive cost savings. Each element aligned with the design concept and brand is strategically merged with the structure and a continuity of colors resulting in curated branding experience.

Communicate any engineering complexities or unique features of the panel design for this project.

All concrete panels were cast on site using casting beds. Because of limited site area, panels were stacked, but not directly. When casting on top of a panel, a layer of earth was added, then another casting bed and then the designed panel. This process ensured that there was no "ghosting" of panel geometry from one to another, and allowed for the order of the panels in the stack to be more flexible. The panels have an unaltered natural finish retaining the purist qualities of the concrete, echoing the iconic concrete architecture of the museums in the adjacent district. They were cast without chamfer at the request of the architect to enhance the refined modern minimalist aspiration of the project. Large panels, the architectural wing wall fronting the street, and multiple spandrel panels supported by steel helped complete the effect. The grade beam along Montgomery was cast with a mix and form system designed to mimic the panel finish. The slab was cast after all panels and structure was in place to eliminate any column base or perimeter cold joints. On the East side the slab thickens and cantilevers 12 feet beyond the tilt wall to support the steel and glass box.

What is the potential for this project's impact on the community and/or environment?

Chroma is a building, a brand, and a business. Shortly after engaging the architect and participating in the concept design process, the client decided to leave his franchise practice behind and create a new identity and brand along with the building. The experience, interior design, architectural design, logo and branding were all developed in unison. The harmony of these elements enhances the impact of the whole.

The architect started work in July 2018, originally tasked with the development of a 6,000 - 8,000 SF building on 4 lots. In February of 2019, after many discussions with city staff and the adjacent residential community, the architect approached the client with an alternative concept that restricted the project to 3 lots. The design was more compact and used an exterior elevated walkway to reduce the footprint of the building. This is the concept that was chosen to move forward and was submitted for permit in the Summer of 2019 and construction completed in the Spring of 2020.

The results for the client have been extremely positive. Dr. Barber reports that "People often come in frame shopping just to "see what it's like inside" and leave with an appointment or a pair of frames." Chroma opened at in March 2020 in the throes of the pandemic, and in-spite of that fact, sales were up 30% from pre-pandemic franchise practice for the first year, and this year are up about 40%.

Project Location

Fort Worth, TX 76102

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

EXCELLENCE

2022

The excellence designation is given to the highest scoring projects each year representing the top 10-12 projects. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Concrete Contractor:

- Architect:

- Iba�ez Shaw Architecture

- Engineer:

- Suppliers:

- Tiltwall Headquarters & Suppliers, LLC

- Photographer(s):

- Dror Baldinger FAIA

Project Specifics

- Project Category:

- Healthcare

- Building Types:

- Clinic

- Finishes:

- Concrete (Raw/Sealed)

- Features:

- Reveals

- Insulation:

- Post Applied (Interior)

- Environmental:

- Number of Floors:

- 1

- Number of Panels:

- 14 panels

- Tilt-Up Wall Area:

- 7,202 sq ft (669 sq m)

- Total Floor Area:

- 5,600 sq ft (520 sq m)

- Project Footprint:

- 5,600 sq ft (520 sq m)

- Tallest Panel:

- 25 ft 11 in (7.90 m)

- Widest Panel:

- 51 ft 1 in (15.57 m)

- Largest Panel:

- 1,324 sq ft (123.0 sq m)

- Heaviest Panel:

- 8,305 lbs (3,767 kg)

- Tallest Cantilever:

- 9 ft 1 in (2.77 m)

- Longest Spandrel:

- 10 ft 7 in (3.23 m)