Why Glue Don’t Work

Español | Translation Sponsored by TCA

By Chad Bruce, president, GluDown, Inc.

Executive Summary

GluDown, Inc. and KRÜSS Scientific has spent the last 18 months measuring tilt-up concrete slabs and the impact of using curing compounds, bond breakers as a curing compound, and applying densifiers to the concrete surface prior to the forming process.

Using KRÜSS’ Mobile Surface Analyzer (MSA) we can measure the surface free energy (SFE) of these slabs and calculate the work of adhesion and interfacial tension between the surface and adhesives, which would be used to bond materials on a Glue Down project or a No Hole project.

We have concluded that chemical curing agents applied to tilt-up concrete slabs fundamentally alter the concrete’s surface free energy.

And in the case of bond breakers and densifiers applied prior to the forming process, they can create an incompatibility between the surface and the adhesive, which can lead to premature adhesive failure. Additionally, it may be necessary to change the timing of applying a chemical agent to the concrete for post forming or panel erection.

We are recommending the creation of a specification for the compatibility between the prepped tilt-up slab and the adhesive to be as follows:

Work of adhesion: ≥65 mN/m

Interfacial tension: ≤7 mN/m

With this standardization, our goal is to minimize unnecessary work and project delays due to curing agent and adhesive incompatibility.

Basics

If you have worked in the tilt-up space during the last decade then you have heard of, seen, or performed a Glue Down project or a No Hole project.

In fact, for many contractors, Glue Down jobs have become the preferred forming process, leaving behind legacy methods such as drilling and nailing materials to the slab.

However, even the best contractor has had a project where it left them saying “glue don’t work.”

In some circumstances, it makes sense for the contractor and their crew to revisit the Spring 2018 Tilt-Up Today article called “Gluing Down: Best Practices” to make sure all the means and methods are being followed correctly. Maybe the crew started forming a little early before the moisture content of the slab dropped below 15% or maybe they did not properly prep the slab and applied the adhesive to dust, creating a poor bond.

But what if they did everything perfectly and still had issues?

Equations and Definitions

In 2020, GluDown, Inc. started researching these problem job sites. What was uncovered was that some growing industry practices are decreasing the surface free energy (SFE) of the concrete slab. This reduction of SFE can cause adhesives to prematurely fail.

In order to understand this study, we need to introduce two equations.

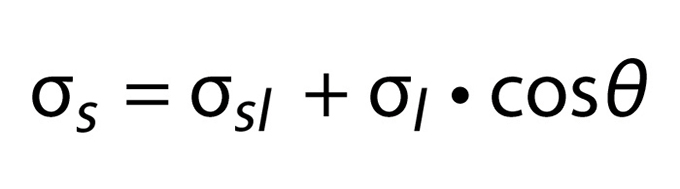

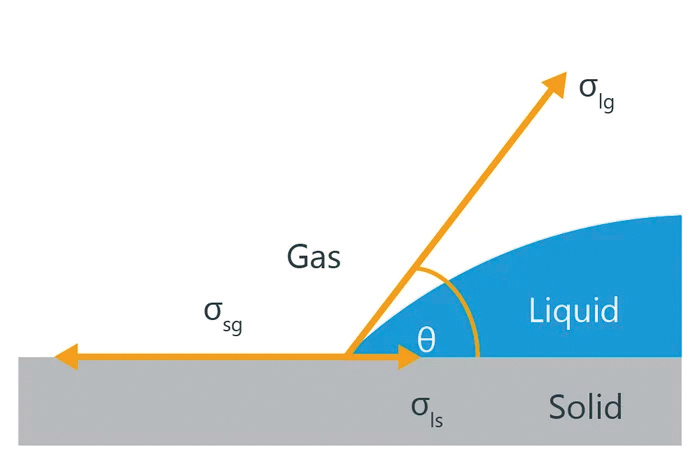

The first is Young’s equation, which states that there is a relationship between the contact angle θ, the surface tension of the liquid σl, the interfacial tension σsl between liquid and solid, and the surface free energy σs of the solid. The contact angle with one or more liquids can be used to determine the SFE of a solid. See image to right.

The second equation states that surface free energy of a solid measured as mN/m (millinewton per meter) is the sum of its dispersive and polar parts:

Surface free energy: σ = σD + σp

σD = disperse surface free energy

σp = polar surface free energy

With these two equations, we can measure the surface free energy of a concrete slab and better understand and predict its compatibility with an adhesive.

The most well-known visual example of a low surface free energy surface is beads of water on a freshly waxed car.

Wax is applied to a car’s paint to protect it from water and build up from debris. It does this by creating a low surface free energy surface on top of the paint. When the paint is exposed to these elements, they are unable to bond to the surface and wick away.

As an alternative, if you sprayed water on a car that had not been waxed in some time, the water will “wet” or spread out and not wick away as easily because it is partially bonding to the paint. This is an example of a high surface free energy surface.

SFE Quick and Easy Measurement

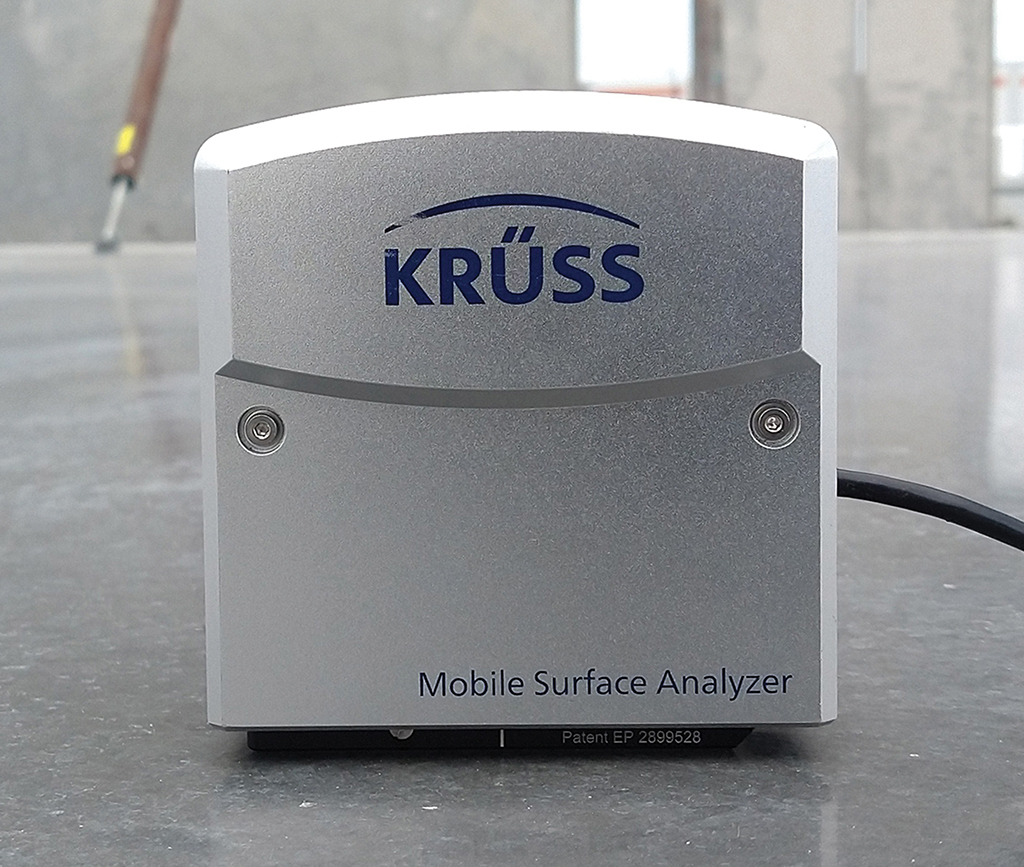

Before we dive into why the surface free energy matters to the tilt-up industry, we want to introduce the tool we used for taking the measurements.

KRÜSS Scientific is a manufacturer of tools that measure surface free energy on almost any surface.Mobile Surface Analyzer

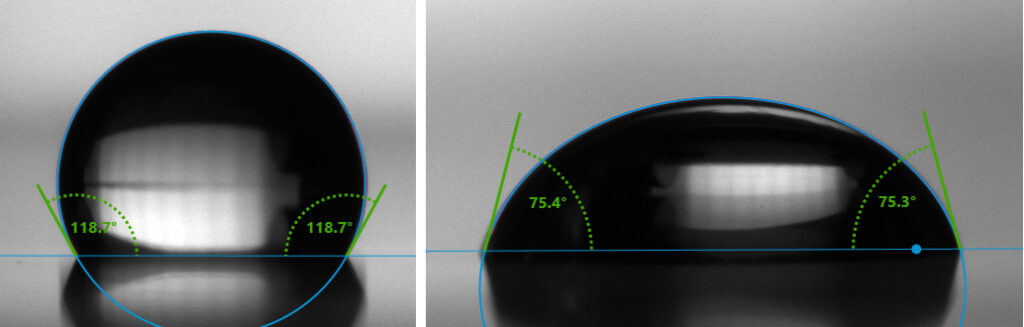

Specifically, their Mobile Surface Analyzer (MSA), which is a compact and portable system, applies two small beads of liquids (water and diiodomethane) onto a given surface. Using contact angles and Young’s equation it can calculate the surface free energy in seconds.

As you see in the images, the system measures the contact angle of the two liquids (water and diiodomethane) applied to a known substrate. Similar to the image of the water on the freshly waxed paint, the two liquids form bubbles on the surface. The system then measures and records the contact angles and calculates the surface free energy. In the test sample above, the water contact angle is 118.7° and the diiodomethane is 75.3°.

Over the course of the last 18 months, GluDown has worked in conjunction with KRÜSS to take the MSA across the United States, measuring tilt-up slab concrete surfaces at a variety of stages in the forming process. And, in doing so, we have cataloged the impact of chemical cures on the concrete’s SFE and how these agents effect the chemical compatibility with the adhesives commonly used in the forming process.

Just Concrete, Nothing Extra

In tilt-up, slabs are often poured in sections and riding trowels along with walk behinds that are used almost immediately to smooth and tighten the surface.

In doing so, contractors provide the new building owner with a beautiful slab foundation and an outstanding casting area for panels.

Additionally, this working of the concrete surface reduces the porosity of the concrete and is an initial step in helping the concrete cure properly.

It is at this moment in concrete’s life where a measurement of its surface free energy is truly just the concrete.

Over the past decades, the industry has changed from blanket cures to now primarily using chemical curing agents such as densifiers, curing compounds, and bond breakers. Each of these chemical agents adds a layer to the concrete’s surface that directly impacts its SFE.

So it is before the application of these agents where our baseline measurement is taken.

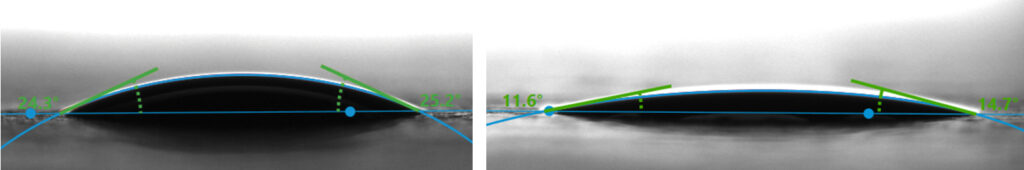

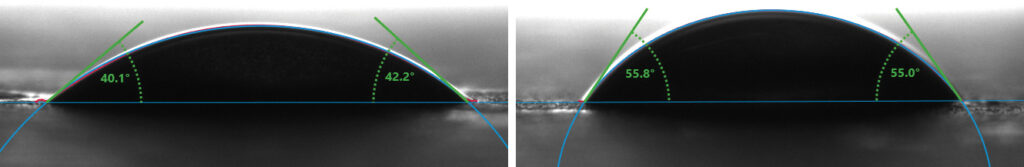

The images below are a typical representation of the droplets of water and diiodomethane applied to bare concrete. As you can see in the image, the droplets have wetted significantly providing low contact angles for both liquids or a high SFE. The water average contact angle is 24.8° and the diiodomethane angle is 13.2°.

In a theoretical world, this high SFE concrete surface is ready for a successful adhesive bond.

However, this is not the world the tilt-up industry operates in today. Schedules have condensed and utilizing a slow curing process such as a blanket cure is no longer common nor feasible.

Hence the introduction of chemical curing agents.

Changing SFE with Curing Agents

We are going to start the discussion on curing agents with the most basic and potentially the oldest chemical agent: a traditional concrete curing compound.

It is important to note that there are a multitude of curing compounds and concrete chemical agents in existence, and it would be a monumental task to test all of them. So, for this study we focused on a select group of common chemicals in each segment.

In general, curing compounds help control the evaporation of water from concrete and, in doing so, prevent shrinkage and cracking. Applying them while the concrete is wet makes the membrane act as a buffer as the concrete dries. But what happens after the concrete is cured? How does this new layer effect the concrete surface?

Using the MSA, we measured tilt-up slabs that had been cured with a curing compound and allowed to dry between 3 and 14 days. The images below show typical contact angles for a concrete surface cured with a curing compound.

What is immediately apparent is that the contact angles of the droplets have increased significantly from the bare concrete. The average water contact angle has increased from 24.8° to 41.2° and the diiodomethane increased from 13.2° to 55.4°. Inversely, the surface free energy of the concrete surface has decreased.

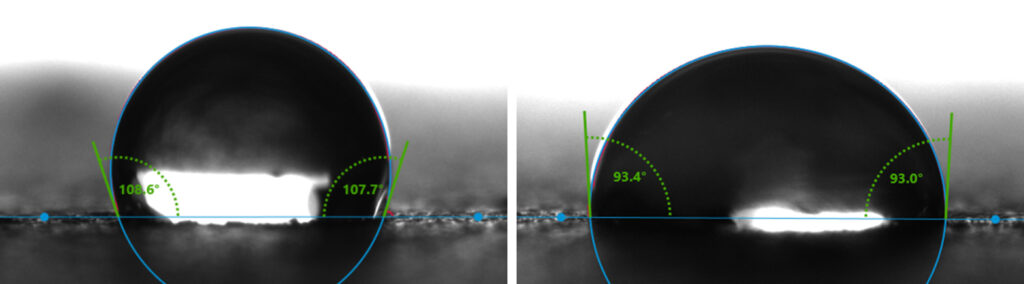

Let’s examine what happens if we take the same measurement of a concrete surface that had a bond breaker applied as a curing compound.

Water – Average Angle: 108.2°

As you can see, the contact angles have increased beyond not only the

bare concrete, but they are substantially higher than the curing

compound. Note the average water contact angle of 108.2° and diiodomethane angle of 93.2°. This provides a near-perfect example of water on freshly waxed paint and demonstrates what the bond breaker does best: prevent bonding.

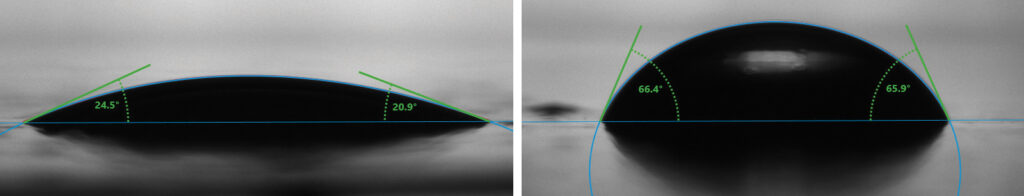

Finally, densifiers are more commonly being used early in the life of the concrete and, in some cases, almost immediately after the pour. Below are the images from a concrete surface where a densifier was applied before any other chemical agent.

In these images you will notice that the formed droplet of water is similar to bare concrete (22.7° average angle) and that the diiodomethane (66.2° average angle) it is more similar to the curing compound. This inverse relationship between the drops and their contact angles will be discussed later in this document.

Quick Vocabulary Terms

In order to put all this information together, we need to define a few terms:

- Work of adhesion (WA) = short-term bond strength

o Think of a Post-it® Note. The first time you stick it on a surface it works well, but over time the bond strength can decrease.

o The higher the number, the better.

- Interfacial tension (YSL) = long term bond strength

o Think of an anchoring adhesive. Once it’s placed and cured the adhesive is extremely strong and not going anywhere without a jackhammer.

o The lower the number, the better.

To go back to the equation of surface free energy (σ = σD + σp), it is important to note that SFE is made up of two components. Depending on how the polar and dispersive attributes of the solid (concrete) and liquid (adhesive) match up, their compatibility changes.

- Polar (σp) = when something has polar surface free energy, it is attracted chemically to water

- Dispersive (σD) = when something has dispersive surface free energy, it is not attracted chemically to water

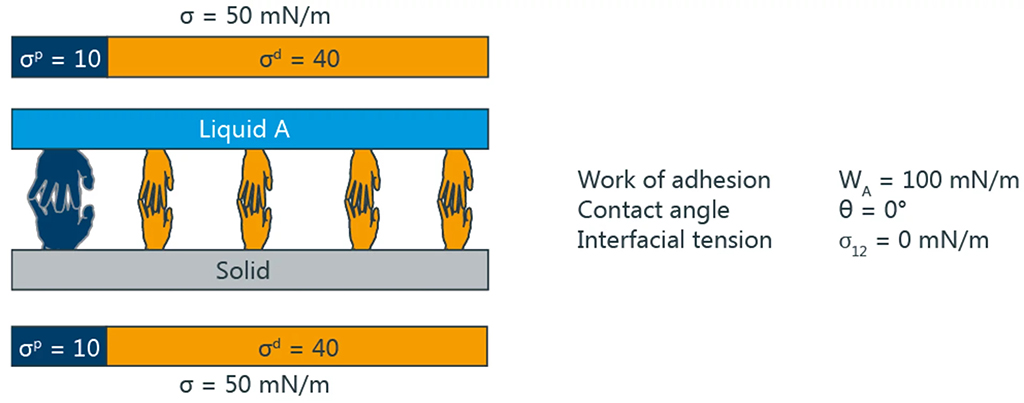

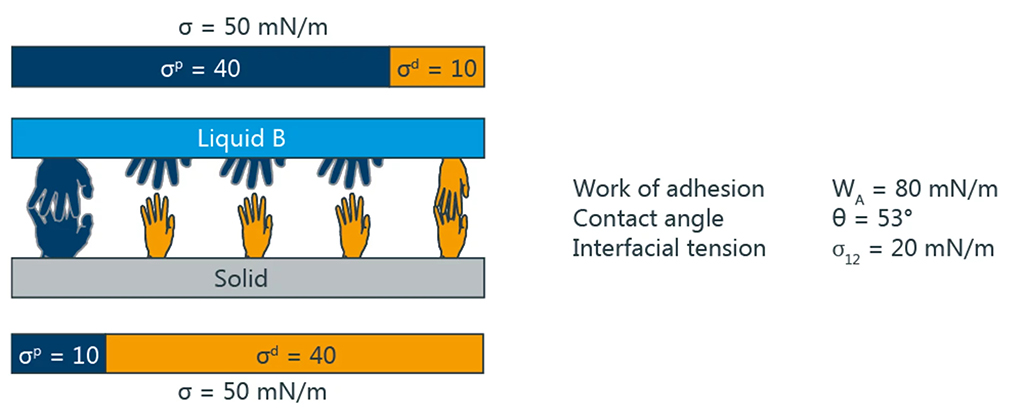

The diagrams below simplify this topic. The blue hands represent a polar surface free energy and the yellow hands represent a dispersive surface free energy.

In this first image, the surface free energy (σ) is 50 mN/m and the polar and dispersive hands match up perfectly, so the interfacial tension is 0 mN/m. This means that the liquid and solid are very compatible.

In the second image the hands do not match, and although the SFE (σ) is still 50 mN/m the mismatching polar and dispersive parts lead to an interfacial tension of 20 mN/m. This is incompatible, which could affect long term bond strength.

What Does it Mean?

We now know that using different chemical agents as curing compounds will directly impact the surface free energy of the concrete slab. And we also know that the hands of polar and dispersive elements of SFE may affect short-term and long-term bond strength of adhesives, but how does this affect a tilt-up project?

Let’s say you wanted to use an adhesive in your panel-forming process, but you wanted to know which chemical curing agent would provide the best opportunity for a successful Glue Down job.

With the MSA and KRÜSS’ Adhesion Analysis tool we provide that information.

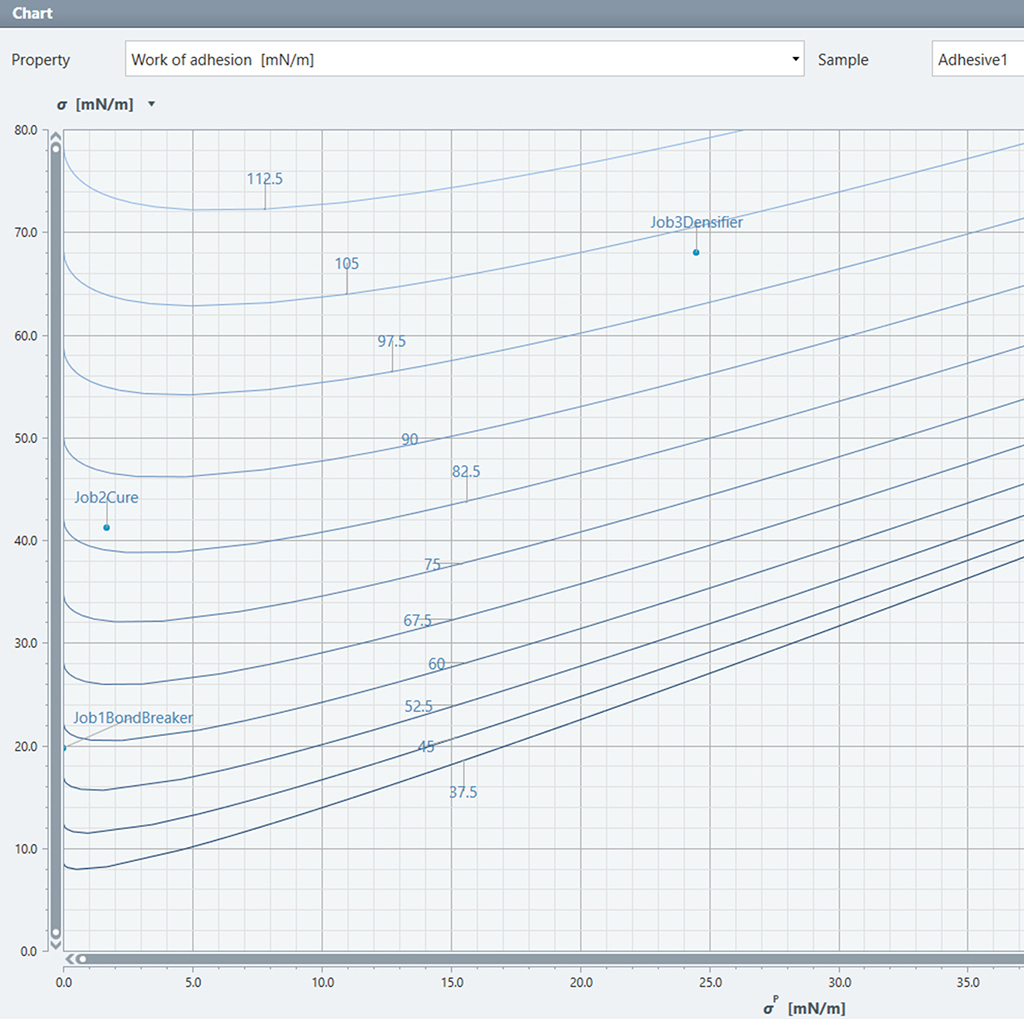

The image above is a contour line graph comparing the work of adhesion for a common tilt-up adhesive (adhesive 1) to SFE measurements from three different job sites, which had three different curing agents applied to the concrete.

What you will see in this chart is that job 1, which had a bond breaker applied, has the lowest work of adhesion at 56.8 mN/m.

Job 2 had a curing compound applied and has a work of adhesion of 84.75 mN/m.

Finally, job 3 used a densifier as the curing compound and its work of adhesion was 102.64 mN/m.

Based on these numbers, the densifier job clearly has the highest (best) work of adhesion and would be the best choice if utilizing adhesive 1 for forming panels.

However, as we learned earlier, work of adhesion only measures short-term bond strength.

And, when the panels are sitting, being exposed to the elements for days/weeks before pouring, we need to make sure the adhesive stays stuck.

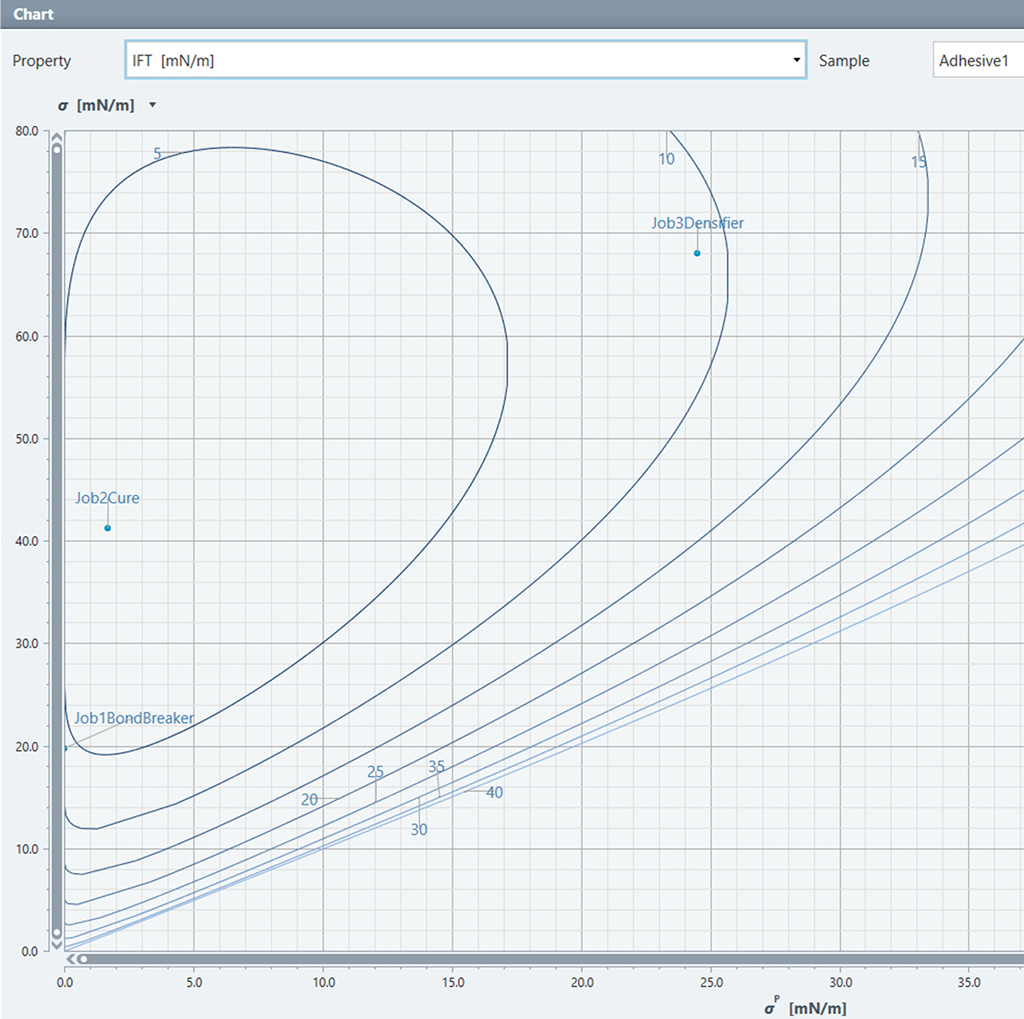

That is where our second graph comes in. It displays interfacial tension or long-term bond strength. Remember: the lower the number the better.

In this graph, the bond breaker in job 1 measured an interfacial tension of 6.85 mN/m.

Job 2 with curing compound measured 0.38 mN/m.

The last site (job 3) with the densifier had a 9.31 mN/m interfacial tension.

Below is a summary table of the graphs for easy comparison:

| Job 1 (bond breaker) | Job 2 (cure) | Job 3 (densifier) | |

| Work of adhesion | 56.8 | 84.75 | 102.64 |

| Interfacial tension | 6.85 | 0.38 | 9.31 |

Key takeaways from this information include the following:

- Curing compound and densifier job site slabs had higher work of adhesion than bond breaker slab

- Curing compound had a near perfect interfacial tension (less than 1 mN/m)

- Densifier had the worst interfacial tension, over 9 mN/m, and is mostly likely for adhesive to fail prematurely

So, if a contractor was choosing the best curing agent for adhesive 1, the curing compound would be the winner.

Additionally, by utilizing a bond breaker or densifier as a curing compound, a contractor would be reducing their adhesive performance and potentially exposing themselves to unnecessary adhesive failures.

But Why Does Glue Not Work?

Adhesives are chemicals. And, at a basic level, using chemicals in combination with other chemicals can lead to compatibility issues.

What we have learned from field-testing concrete curing agents and testing a variety of industry adhesives is that not all of them are compatible with each other.

Remember the contact angle of the densifier cured concrete? The ratio of the contact angles between the water and diiodomethane were different from the other two curing agents. In this circumstance, the densifier created a polar (attracted to water) surface versus a dispersive surface like other two agents.

However, in our example, adhesive 1 has dispersive properties rather than polar properties. So, if a contractor uses adhesive 1 on the slab with a densifier coating, it will create an incompatible environment.

This means that the first time a rainstorm fills the panels up, the densified concrete surface will be chemically attracted to the water. Over time, the concrete will replace its bond with the adhesive in favor of bonding with the water. This will leave the contractor with panels of floating materials. Otherwise known as the title of this article: Glue Don’t Work.

In reality, the adhesive was destined to fail because it was incompatible with the densified concrete surface.

This same example may be applied to any combination of forming adhesives and curing agents.

Specifications, Responsibility, and Accountability

Throughout this project we studied tilt-up jobs, which were both successful and unsuccessful, using adhesives. From this data we are recommending the creation of a specification for the compatibility between the prepped tilt-up slab and the adhesive as follows:

- Work of adhesion target: ≥65 mN/m

- Interfacial tension target: ≤7 mN/m

It is important to remember that these numbers are about compatibility between one adhesive and the cured concrete-slab surface.

As an industry, we need to be accountable to ourselves and provide the best path to success for everyone involved in each project.

Those who specify materials need to understand how their choice of chemical agents applied to the concrete prior to forming can impact the success of a Glue Down job. This information, along with specified work of adhesion and interfacial tension targets, must be communicated downstream to contractors. In addition, they must recognize that the specified chemical agent maybe incompatible with any existing forming adhesive and that the application timing of the chemical agent must be changed when conducting post forming or panel erection.

Contractors must verify compatibility of the specified agent, or their own selection of chemical agents, with suppliers and adhesive manufacturers—prior to forming panels. They also need to understand how their means and methods might need to change based on the combination of chemicals.

If these guidelines aren’t followed, a potentially successful Glue Down job could become an unnecessary headache for everyone involved.

Finally, compatibility alone between an adhesive and the concrete surface does not guarantee success. Tilt-up forming is a complex process, which necessitates adhesives whose performance and design meet the demands of the application. When selecting an adhesive for forming, it’s important that research and testing is done to be sure that the product is both compatible with and performs to the standards of the project.

Final Note

GluDown, Inc. in conjunction with the Tilt-Up Association, is forming a Concrete Slab Surface Energy Committee to further research this topic and to provide the best guidance as the industry continues to evolve.

If you would like to be a part of this committee please reach out to Chad Bruce at cbruce@gludown.com.