Quala Tocancipa

Building owner is a consumer goods manufacturer based in Colombia with operations in the Caribbean, Central and South America, and consisted of:

• National Distribution Center/Raw Material Warehouse.

• Closure of Plants 3 and 4, an existing 5 story cast in place structure.

• Closure of an existing building to serve as the loading dock for the National Distribution Center.

The architect requested the use of ochre concrete (white cement only) and exposed aggregate in all exterior panels. Coal Ash was used as main backfill for the site.

One of the main concerns of the client was the floor slab and its use during construction. The building would house a VNA operation where superflat floors were needed. We produced 40 feet wide, 10” thick superflat floor strips poured out in the open sky and used them as casting beds for tilt-up panels.

Client needed the versatility of making openings across one of the wall to accommodate future manufacturing and distribution needs. We developed the use of in-fill panels that would hang from a main panel without the need of bracing to suit this need. This allowed cutting big openings or simply removing a complete section of a wall.

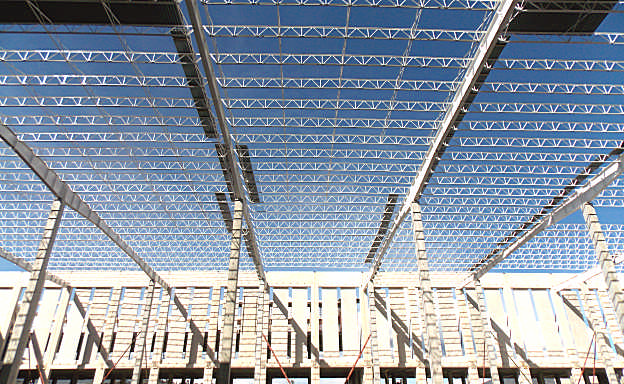

Columns were built using the same concept as Tilt-up Panels, prefabricated on site, and hoisted, several reasons determined this solution, among them:

- Safety, it´s impossible to have a concrete column this tall, for this application, if it´s not a tilt-up column. Steel would require to cover at least the first 20 feet for protection.

- Efficiency, due to the uplift pressures, we needed to add weight to our footings, we took the concrete out of the footing and used it for the column, so the concrete for the columns came at no additional cost.

- Reduced cost, by leaving exposed bars in the footings and columns, splicing them and pouring a secondary stage concrete the full depth and width of the isolation joint left on the floor, we were able to reduce the overall footing thickness and expand the punching shear perimeter for the column.

Plants 3 and 4, was an existing building we enclosed using tilt-up panels, ochre color concrete with exposed aggregate was used. Panels would hang from the edge of slab closing the three upper levels. Panels were casted in the loading dock in operation at the time of construction.

Existing building had no embeds on the edge of slab, we designed a solution that allowed us to install and align the panels.

Another existing building, we enclosed using tilt-up panels with ochre concrete finish was the Administrative Building, its first floor was the loading dock for the National Distribution Center.

Panels were erected below an existing overhang of 13 feet with less than 10 feet of room between top of panel and bottom of the overhang, access for a crane was not possible.

Panels weighed 36,000 pounds and were casted exactly on top of their final position and lifted by using two 10-ton chain hoist by hand.

Project Location

Tocancipa, Cundinamarca

Colombia

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2020

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Concrete Contractor:

- Architect:

- Engineer:

- Suppliers:

- Photographer(s):

- Enrique Guzmán

Project Specifics

- Project Category:

- Distribution

- Building Types:

- Warehouse

- Finishes:

- Concrete (Exposed Aggregate)

- Concrete (Raw/Sealed)

- Features:

- Insulation:

- Environmental:

- Number of Floors:

- 3

- Number of Panels:

- 454 panels

- Tilt-Up Wall Area:

- 245,783 sq ft (22,833 sq m)

- Total Floor Area:

- 238,463 sq ft (22,153 sq m)

- Project Footprint:

- 324,596 sq ft (30,155 sq m)

- Tallest Panel:

- 75 ft 3 in (22.94 m)

- Widest Panel:

- 29 ft 9 in (9.07 m)

- Largest Panel:

- 2,172 sq ft (201.8 sq m)

- Heaviest Panel:

- 147,410 lbs (66,864 kg)

- Longest Spandrel:

- 29 ft 9 in (9.07 m)

- Recycled Content:

- 65,535 tons (US)