Quala Dominicana - CDN Y Planta 4

The Buildings were built for Quala, a consumer goods manufacturer (food, personal care products, home care, snacks and soft drinks) based in Colombia with operations in the Caribbean, Central and South America, and consisted of:

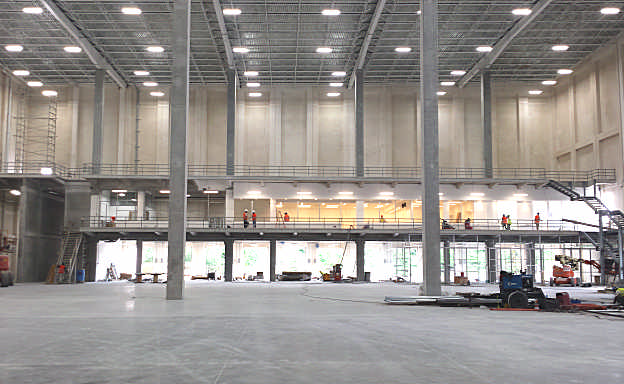

National Distribution Center and Manufacturing Plant no. 4. These two building additions would increase client´s manufacturing and distributing capabilities for the Dominican Republic and the Caribbean.

The building architect requested the use of ochre concrete (white cement only) and exposed aggregate in all exterior panels, which posted a challenge due to aggregate availability to consistently achieve a uniform exterior finish.

National Distribution Center building operation required the use of superflat floors for the specified VNA traffic. Panels were constructed on those superflat floors that were used as casting beds, poured in 40´ wide strips in extremely hot and humid weather.

The west wall of the NDC Building was designed with the versatility of connecting to future manufacturing plants. To suit this need, we developed further the use of in-fill panels that would hang from a main frame without the need of bracing at the time of installation. Making it easy to open or close large openings in the wall.

The same use of this innovation was applied in Manufacturing Plant No. 4 for its south and west walls, allowing connection to future manufacturing plants.

As an architectural feature, and complementing the natural ventilation of the National Distribution Center building, prefabricated lattices were built in concrete and installed in the east wall openings.

As a structural solution on Manufacturing Plant No. 4, main loading structure (columns and beams) were built using the same concept as tilt-up panels, prefabricated on site and hoisted.

Some of the panels were designed to be used as shear walls on both directions, on top of pile caps.

All columns were designed to be installed onto pads and connected to the footing by splicing column and footing rebar and pouring a secondary stage concrete in the void created by the isolation joint left on the floor. This allowed us to reduce our overall footing thickness and expand the punching shear perimeter of the column.

Manufacturing area was designed using natural ventilation utilizing concrete thermosyphons, and natural light with custom made concrete skylights.

Project Location

Haina, San Cristobal

Domican Republic

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2020

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Concrete Contractor:

- Architect:

- Engineer:

- Suppliers:

- Photographer(s):

Project Specifics

- Project Category:

- Distribution

- Building Types:

- Distribution Center

- Finishes:

- Concrete (Raw/Sealed)

- Features:

- Insulation:

- Environmental:

- Number of Floors:

- 4

- Number of Panels:

- 215 panels

- Tilt-Up Wall Area:

- 184,360 sq ft (17,127 sq m)

- Total Floor Area:

- 76,392 sq ft (7,097 sq m)

- Project Footprint:

- 107,693 sq ft (10,005 sq m)

- Tallest Panel:

- 77 ft 5 in (23.60 m)

- Widest Panel:

- 32 ft 9 in (9.98 m)

- Largest Panel:

- 2,462 sq ft (228.7 sq m)

- Heaviest Panel:

- 159,538 lbs (72,365 kg)

- Longest Spandrel:

- 26 ft 6 in (8.08 m)