Project Location

,

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Concrete Contractor:

- Architect:

- Engineer:

- Suppliers:

- Photographer(s):

Project Specifics

- Project Category:

- Building Types:

- Manufacturing Plant

- Finishes:

- Concrete (Raw/Sealed)

- Paint (Flat)

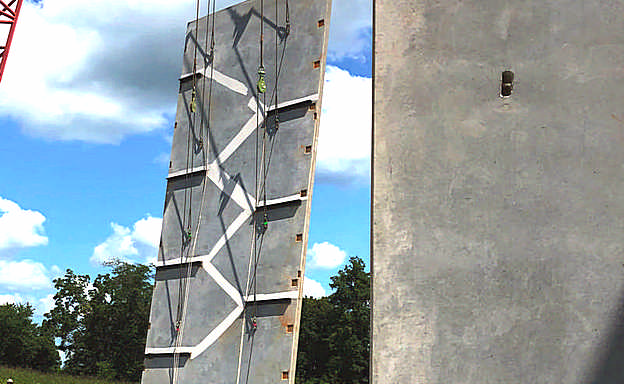

- Features:

- Embedded Items

- Interlocking Panels

- Reveals

- Stacked Panels

- Voids

- Insulation:

- Uninsulated

- Environmental: