Recreation Center of the Qatar Academy in Al-Khor

Project summary provided by submitting company.

The structure acted as the recreation center for the QAK school. This recreation center building encompasses a main dining hall, kitchen area, 2 gymnasiums, an Olympic size swimming pool and other function areas.

The building's core consisted of 8" and 10" Tilt-Up shear walls and steel columns, while the shell was made of 12" and 15" insulated tilt walls in its entirety with the exception of main entrance curtain walls. Roof diaphragms were composed of structural steel frames, topped by 5 inches thick structural screed for the low roofs, while insulated sandwich panel decking was used for the high roofs. All roofs bear on external tilt panels, internal tilt panels and steel columns. Biggest spans between columns was 26m.

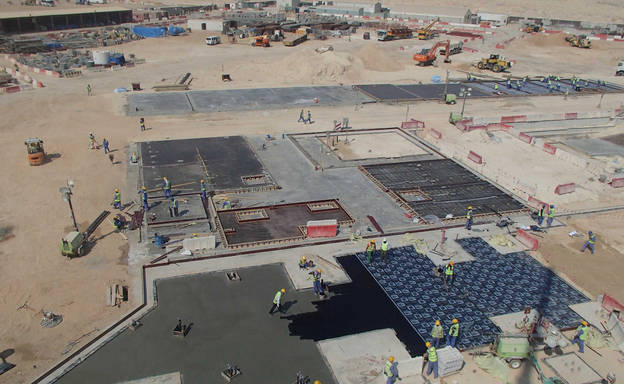

The construction of this irregularly shaped building required high levels of coordination to achieve the desired outcome in the time that was given, and the tight area that the site had to offer. The construction program was identified from the start identifying the need to finish both wings (gymnasiums) first, then working out the interior of the central main structure before leaving out from the back side where the pool area was and closing of the exterior panels which were cast on a strategic sacrificial casting bed. This tactic enabled other trades to do their work unhindered from Tilt-Up pouring & erection activities while also clearing the coast other trades that come after Tilt-Up walls setting to come in and do their work earlier than originally anticipated as per the conventional construction program.

The project was re-designed from conventional concrete construction to construction using Tilt-Up, after the Tilt-Up contractor/specialist convinced the general contractor and the Client that the Tilt-Up system will reduce cost and expedite the construction process, where the Tilt-Up contractor also carried out the redesign of the project. This value engineering in switching to Tilt-Up resulted in achieving around 15% cost savings (of the skeleton works' budget) for the General Contractor (GC) and the client; thus, securing the contract for the GC.

A certificate of award was presented to the main contractor in recognition of outstanding safety performance (500,000 Man Hours without LTI) due to the inherent nature of tilt up having more work done on ground level than at elevations, and the ease at which the job location housekeeping can be maintained.

Special challenges faced during the Project:

- High temperature conditions (reaching 55 Celsius): makes it difficult for workers, and cannot cast concrete during daytime

- Part of the structure was built on embankment, so piling had to be put in place for the foundations

- Sand storms: Sandstorms and dust can delay casting of concrete, because the bond breaker needs to be re-applied after the panel has been cleaned up after dust.

- Wind speeds reaching over 100 km/hr: this delayed erection of panels as erection halts when the wind speed picks up

- Because hollow core slabs were to be mounted inside, the bracing could not be fixed inside the building

Three top reasons this project should be considered for a Tilt-Up Achievement Award:

- Due to using Tilt-up, the contractor and the client saved about 15% of the skeleton works budget

- Highly decorative exterior features (reveals, recesses & protrusions), complex tilt-wall pouring layouts and formations to meet strict hand-over deadline and tight area.

- Adaptability of the tilt-up system to the project's requirements and footprint, as the project was initially planned as conventional, and speed of panels production and erection in 2 months

Successes of the project:

- The needed quantity of timber form-work was reduced by almost 90%, due to the tilt-up system of construction.

- Because of using tilt-up, there are less workers' safety hazards from working at heights and falling, since most of the work is done on the ground slab. The project received a safety award of: 500,000 Safe Man Hours

- Due to the use and implementation of the tilt-up system, the number of workers was reduced by almost 50% than needed in conventional construction, so less workers are exposed to health and safety hazards

- Due to using tilt-up as the construction method, the Contractor and Client saved about 15% of the skeleton works budget.

- Major reduction in construction material Waste.

- Major reduction in Transportation activities related to the construction process (Less CO2 emissions as a result).

- Major reduction in future maintenance as a result of using Tilt Up Vs. Conventional construction.

- Energy Saving as a result of delivering Insulated Panels.

Project Location

Al Khor, Al Khor

Qatar

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- SiteCast General Contracting Co.

- Concrete Contractor:

- SiteCast General Contracting Co.

- Architect:

- Engineer:

- SiteCast General Contracting Co.

- Suppliers:

- Photographer(s):

- SiteCast GCC

Project Specifics

- Project Category:

- Sports / Recreation

- Building Types:

- Gymnasium

- Training Facility

- Finishes:

- Paint (Flat)

- Paint (Textured)

- Stucco

- Features:

- Angled Panels (Elevation-Edge/Shape)

- Angled Panels (Plan-Orientation/Position)

- Cantilevered Panels

- Interlocking Panels

- Reveals

- Stacked Panels

- Insulation:

- Sandwich Panel (Composite)

- Environmental:

- Number of Floors:

- 2

- Number of Panels:

- 152 panels

- Tilt-Up Wall Area:

- 96,341 sq ft (8,950 sq m)

- Total Floor Area:

- 140,254 sq ft (13,030 sq m)

- Project Footprint:

- 136,535 sq ft (12,684 sq m)

- Tallest Panel:

- 40 ft 4 in (12.29 m)

- Widest Panel:

- 24 ft 6 in (7.47 m)

- Largest Panel:

- 858 sq ft (79.7 sq m)

- Heaviest Panel:

- 107,800 lbs (48,897 kg)

- Tallest Cantilever:

- 8 ft 6 in (2.59 m)

- Longest Spandrel:

- 54 ft 2 in (16.51 m)