Bath Fitter

Summarize the project's program, features and achievements.

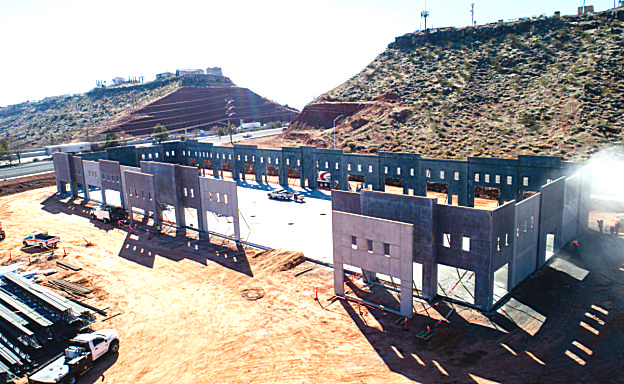

Bath Fitter is a 41,628 square foot, two-story building located in Washington, Utah. It is comprised of 12 individual 2,700 square feet (roughly) units that feature an additional 880 square foot mezzanines. The well-crafted integrally colored and sandblasted tilt-up walls create variation, texture and dimension. In addition, the wall panels were over-lapped and staggered at different heights to add further architectural interest. This highly visible project just off of I-15 generates appeal for other companies to use exposed architectural tilt-up as it will last many years and require little maintenance. Due to the small site and surrounding slopes, retaining walls were constructed before the building to create enough swing space for the crane to erect the wall panels. The project was completed both on time and on budget despite times of such uncertainty. The entire project team constantly reviewed the work to ensure it exceeded client expectations. Open communications with all parties in weekly coordination meetings, the use of technology, and regular walk-throughs helped keep all levels of workers on a high standard of quality. Bath Fitter will benefit for years to come with very little maintenance costs and high energy efficiency with this building.

What obstacles were overcome related to the schedule, budget, program, specification, site, etc. on this project?

Hughes General Contractors takes great pride in making sure that our clients are happy with their building. Bath Fitter was no exception as we worked diligently with the client to ensure the color and sandblasting choices for the tilt-up panels were the exact style they were searching for. Hughes' in-house design team creates our own tilt-up shop drawings to provide crews with accurate and verified details & dimensions. Using these accurate shop drawings to construct panels allows our concrete workers to pour and lift panels to exact specifications for a near-flawless result. The drawings also ensure panels are lifted correctly as to prevent cracking. Hughes faced a great challenge of keeping the project on budget due to the cost of materials escalating. To combat the issue, tilt-up concrete was used as the least volatile method of construction as well as providing a beautiful, durable and cost efficient structure.

What is the potential for this project's impact on the community and/or environment?

Because of the great visibility of the site, this concrete tilt up project has and will continue to generate interest for other companies to use tilt up as a means of construction that that will last many years and require little maintenance.

Project Location

St George, UT 84770

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

ACHIEVEMENT

2022

The world’s greatest tilt-up structures are featured by the TCA as Tilt-Up Achievement Award Winners. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Hughes General Contractors, Inc.

- Concrete Contractor:

- Architect:

- Engineer:

- Suppliers:

- Photographer(s):

Project Specifics

- Project Category:

- Retail

- Building Types:

- Store

- Finishes:

- Concrete (Raw/Sealed)

- Features:

- Voids

- Insulation:

- Post Applied (Interior)

- Environmental:

- Number of Floors:

- 2

- Number of Panels:

- 58 panels

- Tilt-Up Wall Area:

- 24,149 sq ft (2,243 sq m)

- Total Floor Area:

- 41,628 sq ft (3,867 sq m)

- Project Footprint:

- 31,628 sq ft (2,938 sq m)

- Widest Panel:

- 27 ft 7 in (8.41 m)

- Largest Panel:

- 550 sq ft (51.1 sq m)

- Heaviest Panel:

- 52,141 lbs (23,651 kg)