Fort Worth Camera

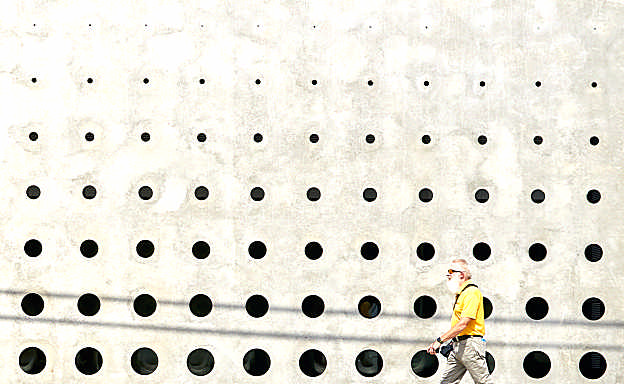

One of the primary drivers in the design of the project was a concern about security. It was inevitable that this protective concrete wall was going to be the dominating face of the building. The pattern of holes depicts seven standard aperture proportions, something identifiable and recognizable to the community of photographers visiting the building. In studying the wall in the three dimensions the architect discovered that flaring these “holes” allowed more transparency. The thickness of the wall is “hidden” by flaring the hole at a steeper angle than that of the viewer. This gives the impression from the Montgomery street that the wall is only inches thick and allows more light to penetrate through to the courtyard and interior spaces.

The aperture wall on Montgomery is 16 feet tall and 53 feet long, cast with 175 holes. The other tilt-wall panels used in this project are thirty to forty feet long, and 21 feet tall. Casting beds were used to create enough casting surface for the required panels and to avoid any finish disturbance from the slab. The upper panels were set with a few inches of cantilever and a reveal joint to set them apart from the cast-place wall below.

The aperture wall was cast on the upper part of the site and lifted by crane to situate the panel just a few feet off of Montgomery street. The wall has an array of 25 rows of 7 conical shapes. The forms for the conical holes were fiberglass molds that were vacuum formed from milled wood shapes. Each of the 7 shapes were fashioned from solid laminated wood by Terry Pulliam, and subsequently vacuum formed 25 times to make the 175 required forms for the wall. Because the cones were to be used with their small side down in the panel, foam was not an option as it would have been disturbed too easily during construction. The heavy-duty fiberglass cones were secured by screws to the casting slab at their end and filled with sand to maintain their shape. They were topped with a shallow layer of grout to keep the sand from contaminating the surrounding concrete. The tilt-wall method allowed for great access to the conical forms ensuring exact placement and proper consolidation of concrete. The fiberglass forms and special attention from Pulliam Concrete created a beautiful smooth finish on the concrete that carries from the exterior through the conical shapes.

The finish on the panels is an unedited (no patching, rubbing or paint) exhibition of the natural qualities of concrete. This naked presentation requires skilled craftsmanship as deficiencies in accuracy and quality standout adversely and distract from the expected variations of concrete’s materiality.

The aperture wall holds a powerful presence on the street and has made the building somewhat of a landmark in the city. The wall became such an identity forming element for Fort Worth Camera that they rebranded using the aperture wall graphic as a basis for their new logo, and corporate identity.

Project Location

Fort Worth , TX

United States

TILT-UP ACHIEVEMENT AWARD

The Tilt-Up Achievement Awards were established to honor projects that use site-cast tilt-up concrete to introduce new building types, advance industry technology and provide unique solutions to building programs. Winning entries illustrate the variety, beauty, and flexibility of tilt-up construction.

EXCELLENCE

2020

The excellence designation is given to the highest scoring projects each year representing the top 10-12 projects. Learn more >

Project Images

Project Team (TCA Members)

- Developer/Owner:

- General Contractor:

- Concrete Contractor:

- Architect:

- Iba�ez Shaw Architecture

- Engineer:

- Suppliers:

- Photographer(s):

- Dror Baldinger

- FAIA

Project Specifics

- Project Category:

- Retail

- Building Types:

- Finishes:

- Features:

- Insulation:

- Environmental:

- Number of Floors:

- 2

- Number of Panels:

- 10 panels

- Tilt-Up Wall Area:

- 7,000 sq ft (650 sq m)

- Total Floor Area:

- 9,800 sq ft (910 sq m)

- Project Footprint:

- 11,100 sq ft (1,031 sq m)

- Tallest Panel:

- 23 ft 3 in (7.09 m)

- Widest Panel:

- 52 ft 4 in (15.95 m)

- Largest Panel:

- 930 sq ft (86.4 sq m)

- Heaviest Panel:

- 84,281 lbs (38,229 kg)

- Tallest Cantilever:

- 21 ft 10 in (6.65 m)