By Abbie Stolte, Tilt-Up Concrete Association

In a region known for its natural beauty and construction complexity, a quietly growing tilt-up movement is taking hold in Hawaii. Led by firms like Honolulu Builders LLC and supported by local suppliers like Atlas Sales Co., the method is gaining traction for its practicality, predictability, and untapped design potential. But as several Hawaii-based leaders point out, tilt-up in the islands still faces a fundamental obstacle: It’s not considered soon enough.

During a recent interview with the Tilt-Up Concrete Association (TCA), four members of the Honolulu Builders team—Dan Jordan (principal), Justin McCarthy (superintendent), Tim Sinn (project manager), and Subbu Venkataraman (principal)—spoke candidly about the opportunities and challenges of delivering tilt-up projects across the Hawaiian Islands. Their experience reflects a common theme: Tilt-up works here, and it works well, but more owners and architects need to understand its full value.

Hanua Warehouse — At 226,000 square feet with 42 dock doors and 40-foot interior clearance, this project set a state record as the largest tilt-up building in the Hawaiian Islands. Crews also set a performance milestone, erecting 30 panels in just 8 hours—the most panels ever lifted in a single day in Hawaii.

“One of the biggest barriers to tilt-up in Hawaii,” said Jordan, “is that by the time we get involved, the building has already been drawn as steel. Tilt-up doesn’t even make it into the conversation.”

Sinn agreed, emphasizing the difficulty of introducing a different delivery method once the documents are well underway. “It’s a heavy lift to try and shift direction once the design is locked in,” he said. “But when we do get the opportunity to use tilt-up from the start, the results speak for themselves.”

Due to Hawaii’s unique terrain, tilt-up offers compelling advantages. Local concrete can be sourced more reliably than imported steel or prefab panels. Self-performing trades improve quality and scheduling. And, in a state where time and logistics are everything, casting panels on-site can help contractors avoid costly shipping delays. McCarthy emphasized the method’s simplicity and control: “It’s a cleaner process once you’ve done it a few times—it’s faster and more streamlined.”

He also noted that tilt-up allows for more predictability on-site. “With some of our larger projects, we knew we were going to hit delays if we waited on structural steel or long-lead imported materials. Tilt-up gave us the control we needed to stay on track.”

Subbu, a structural engineer by background, pointed to broader implications. “We need to change the conversation early,” he said. “It’s not about just pitching tilt-up after the fact. It’s about being part of the project definition, helping shape the approach from the start.”

This theme—earlier collaboration, deeper understanding—resonated beyond Honolulu Builders. Gary Camp, president of Atlas Sales Co. Inc., has worked closely with the firm on numerous tilt-up projects. As a regional distributor of Leviat products, brace systems, and Nox-Crete form release agents, Atlas plays a key role in the supply chain. Recently, the company hosted a hands-on open house, pouring demonstration panels to engage new contractors.

“Honolulu Builders has laid claim to the number one premier tilt-up contractor in Hawaii,” Camp said, noting that others across the state are beginning to embrace the method as well. He pointed to a recent increase in large-scale tilt-up projects under construction and new self-developed facilities opting for tilt-up solutions, which signals a broader shift in the market.

Camp also underscored the importance of contractor education and product support. Atlas works directly with builders to supply not only engineering and shop drawings via Leviat but also hands-on support for brace layout and hardware coordination. “We’re not just selling product. We’re helping people get it right—especially when things get complicated.”

Together, these efforts point to growing momentum. But the group agrees: For tilt-up to thrive in Hawaii, the local design and development community must recognize it as more than a big-box solution. “There’s no reason tilt-up can’t be part of the architectural conversation here,” said Venkataraman. “It’s not a compromise. It’s a choice—with cost, schedule, and design benefits.”

“Architects think they’re giving something up when they use tilt-up,” added Jordan. “But we’ve seen buildings with articulation, window depth, reveals, and all the things they want. If it’s planned well, the results can be beautiful.”

The team at Honolulu Builders is eager to expand that message. McCarthy, who has overseen complex panel layouts in challenging jobsite conditions, sees education as the next step. “We need to bring more people into this conversation—from the design side, from ownership, from engineering. There are so many ways tilt-up can make projects better.”

McCarthy also emphasized the company’s leadership role in workforce development. He said, “We see it as our responsibility to help shape the future of construction in Hawaii,” he said. “We’re working directly with Hawaii’s carpenter apprentice classes, not just to teach the basics, but to introduce the next generation to advanced tilt-up methods. The support we’ve received from the TCA has been instrumental in this effort. Without that guidance and community, we wouldn’t be where we are today—as the state’s leading tilt-up contractor on the forefront of innovation.”

As the state continues to balance development needs with resource constraints, tilt-up offers a smart, sustainable approach. But its future depends on a cultural shift—one that starts with awareness, education, and early inclusion.

The people advancing tilt-up in Hawaii are ready. The question now is whether the broader industry will catch up.

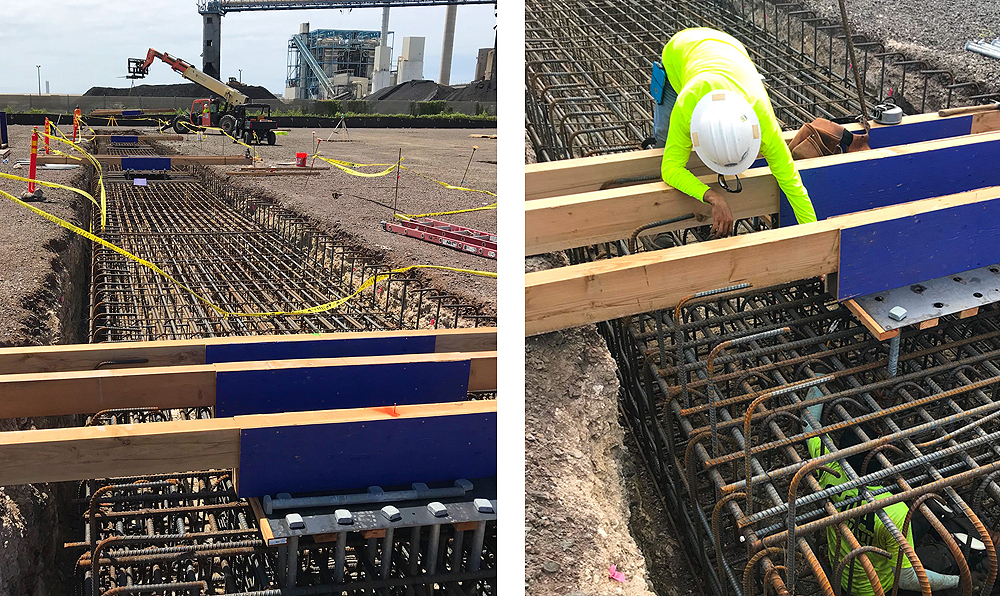

Innovative Seismic Design — To divide the 1,500-foot building into three independent seismic sections, a massive grade beam was created for the moment frames. Working closely with engineers, a custom metal plate system was designed in CAD, forged, and refined through multiple iterations to ensure the huge columns and panels could move separately during an earthquake. The solution introduced 4-inch gaps in four sections of the structure—an unprecedented approach in Hawaii—while maintaining structural integrity. A parapet was also constructed atop the decking to move with the building.

Kapolei Harborside Warehouse — Spanning 110,000 square feet with 25 dock doors and a 36-foot interior clearance, this facility delivers modern capacity and efficiency to Hawaii’s growing industrial market.

Be the first to comment