By Eohan George, Cofounder of SkyMul

When constructing a data center, tilt-up panels aren’t just structural elements—they’re critical schedule drivers and cost multipliers. With critical embeds, tight sequencing, and zero room for reworking once they’re set, precision is nonnegotiable. Beneath these panels lies a dense web of underground utilities from multiple trades, where frequent relocations and layout mistakes can trigger a chain reaction that disrupts panel placement, crane logistics, and follow-up work.

The QC Burden for Tilt-Up Panels

The quality control (QC) challenge in tilt-up work is staggering. A single panel might require checks on two dozen non-rebar elements, plus rebar placement, totaling around 50 individual verifications. On a 100-panel building, that adds up to more than 5,000 items—each of which must be correct to avoid rework.

The cost of getting it wrong is steep. Minor fixes can run into the hundreds, while replacing a panel can sometimes exceed $100,000. And, beyond direct costs, errors can trigger crane-day delays, push back other trades, and erode client confidence.

QC inspections are often crammed into the narrow window available before a pour. Crews rush through verifications with binders or PDFs of shop drawings that are hard to navigate in the field. Add in the frequent design changes and shifting site conditions typical of architectural projects, and the risk of missed or incorrect checks only grows.

SkyMul’s Approach: Fast, Accurate, Context-Rich QC

Recent deployments have shown that high-speed, precision aerial scanning can change the way tilt-up QC is done. Using drones, site scans can be completed in 15 to 30 minutes, achieving ¼-inch accuracy in XY position and ½-inch accuracy in elevation.

“With SkyMul, we scanned the site at 4:00 p.m., had results back by 7:00 p.m., and confirmed everything was as it should be well before the 1 a.m. pour. That kind of turnaround makes drone scanning an important part of our program, enhancing real-time quality control and ensuring the results our customers and project owners expect.” —Steven Thomas, vice president of Project Management, Quality, and Technology for Martin Concrete Construction Inc.

Martin Concrete Construction Inc., a leading concrete contractor, consistently pushes the industry forward by leveraging technology and innovative processes. This approach elevates the company’s work, delivering exceptional results for customers and project owners alike. SkyMul’s collaboration with Martin Concrete is helping to explore new ways to advance the field and set a higher standard for construction excellence.

On recent projects, this same workflow has prevented tens of thousands of dollars in potential rework by identifying issues early enough to ensure seamless correction—avoiding schedule slips and costly field fixes. The results are easy to see in practice.

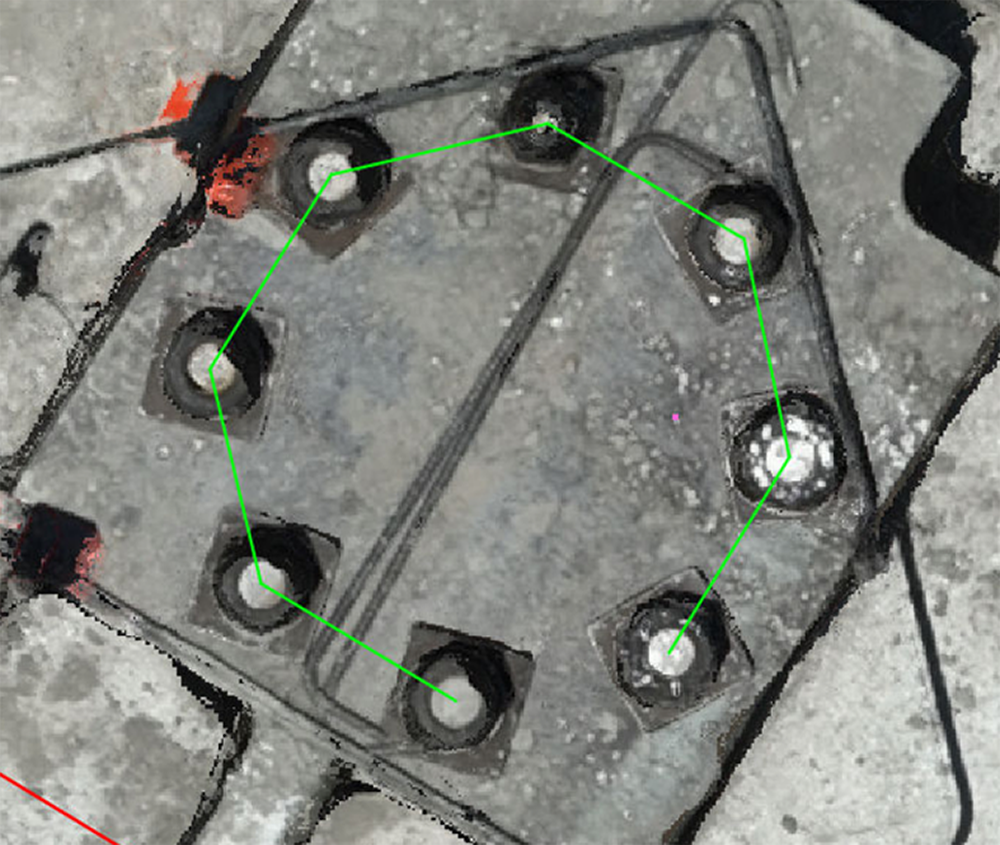

Left: Missing embeds identified during the forming process.

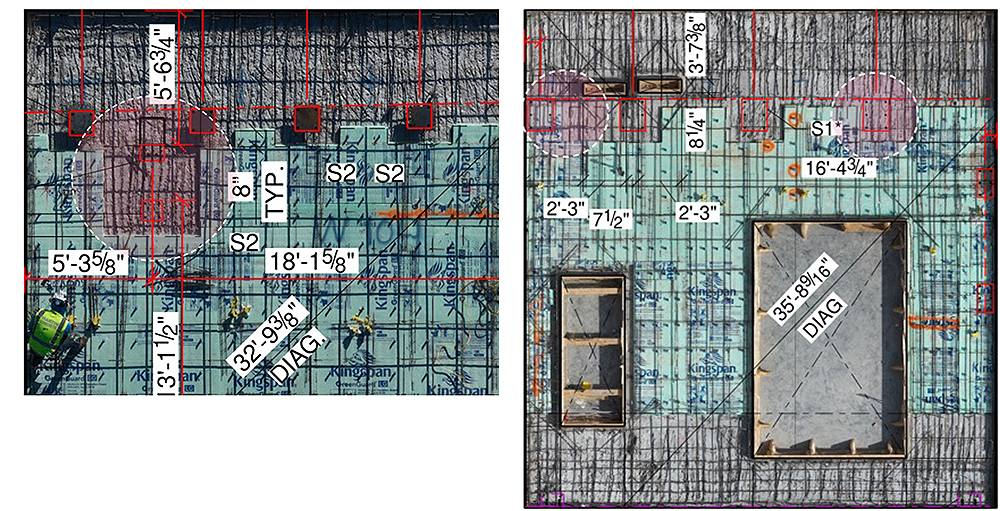

Right: Insulated panel installed wrong-side up, which interfered with embed placement.

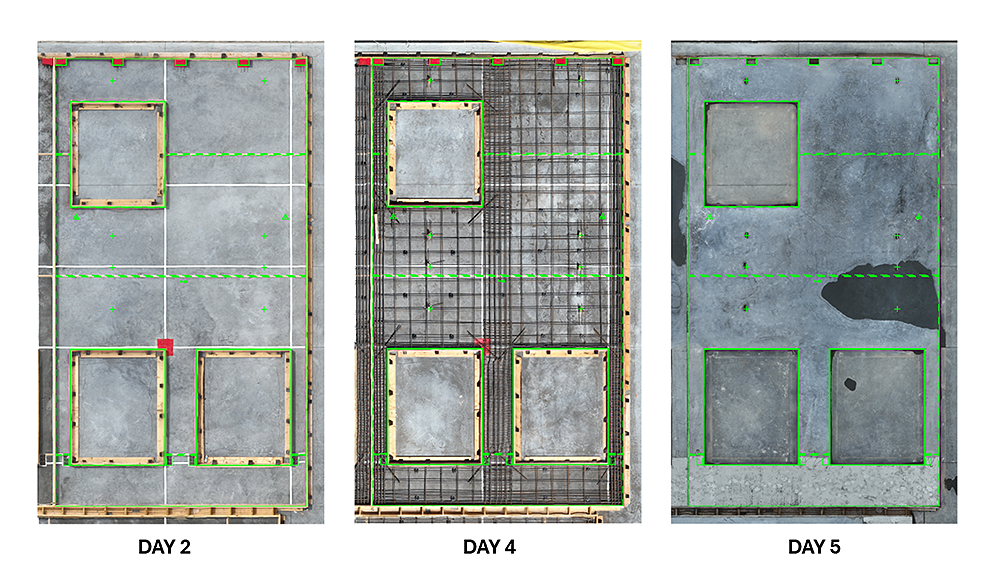

Beyond individual panels, the same dataset can be used to visualize and manage production over time.

Visualizing Progress Over Time: Multiday panel view generated from daily scans that show assembly sequence, track installation pace, and flag schedule variances in real time.

Visualizing Progress Over Time: Multiday panel view generated from daily scans that show assembly sequence, track installation pace, and flag schedule variances in real time.

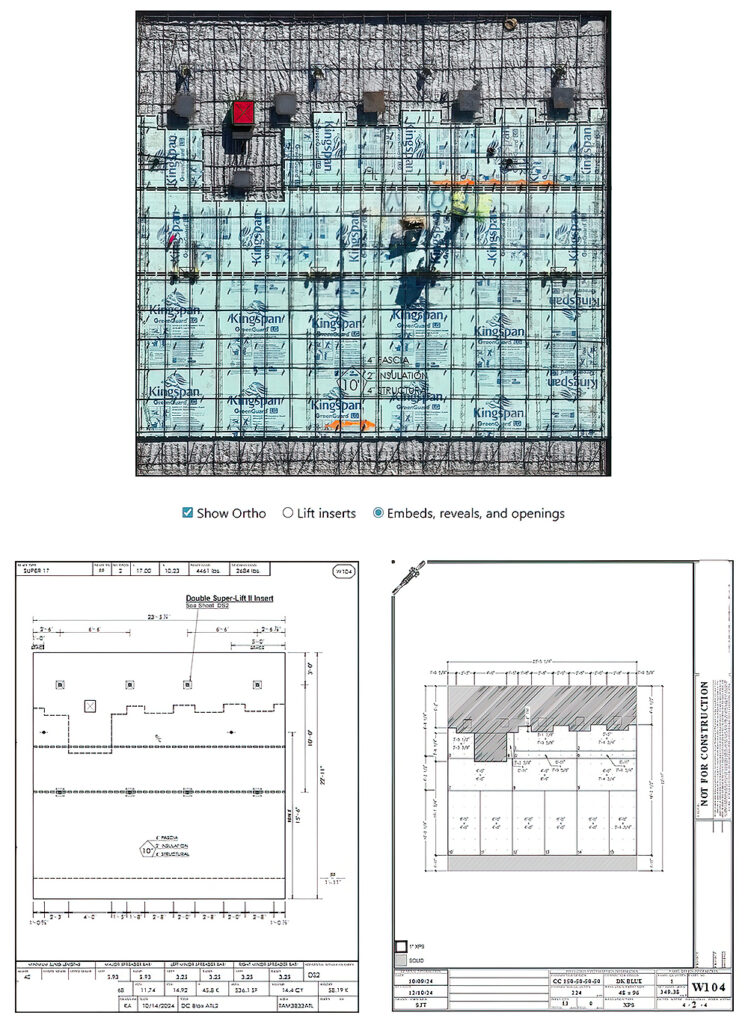

Field crews often reference shop drawings that fill thick binders or PDFs that are several hundred pages long, causing them to be slow to search and easy to misinterpret as conditions change. SkyMul syncs the latest office-issued drawings directly into the live digital twin, creating a seamless feedback loop between the field and the office and back to the field.

Beyond Panels: Solving Other Project Management Pain Points

While panel accuracy remains a primary focus, the same scanning approach unlocks efficiencies across the broader project lifecycle.

- Early Identification of Conflicts and Stub-Ups: Detects potential clashes and misplaced stub-ups well before crews focus on an area, preventing impacts to forming, slab placement, and pours.

- Adapting to Frequent Design Changes: Footing positions and panel layouts often shift after work begins. SkyMul’s digital twins integrate the latest drawings with current site conditions, keeping all stakeholders aligned and reducing confusion.

- Rough Grade Verification: Half-inch elevation accuracy enables contractors to assess rough grading work from other teams before survey crews need to spot-check it. This early insight helps coordinate fine grading, improving efficiency and saving time.

- Managing Asynchronous Concrete Activities: Digitally tracks footing and slab pours and provides clear records of timing, volumes, and locations. This reduces invoicing errors and the communication overhead required to reconcile work.

- Crane Path and Site Preparation Validation: Confirms that critical logistics areas, such as crane paths, are properly compacted and ready, avoiding costly delays.

- Coordinate System Consolidation: Merges GPS latitude/longitude with local project grids into a single navigable view, supporting both satellite-based verification and robotic total station workflows.

- Archival Documentation for Accountability: Daily scan archives provide a definitive record of progress. These records help clarify impacts from weather delays, design changes, or sequencing conflicts, which minimizes disputes between contractors and owners.

Integrated Shop Drawings with Digital Twin: Crews in the field can tap a panel to see its exact design intent, while office staff can pull up that same location to view its real-time status—reducing the risk of building from outdated plans.

Risk Reduction and a Cultural Shift in QC

Traditionally, the construction industry has relied on drone footage in a defensive, after-the-fact manner—primarily for “cover-your-assets” situations, litigation support, or documenting progress for later reference. SkyMul is shifting this approach. By making scans affordable, daily, and actionable, the company is turning drones from static insurance records into active production tools.

The future concrete contractor won’t just pour concrete—they’ll own the data layer of their work. This approach lowers the barrier to high-granularity QC by enabling a truly distributed process—team members, both those based in the office and those who work remotely, can review precise, current site conditions and contribute to decision-making without being physically present. By taking responsibility for drone scanning, concrete contractors can stop being reactive to information from other contractors and start driving the conversation. When every stakeholder—from the owner to the ironworker—works from the same daily-updated digital twin, coordination moves from hopeful to precise. Integrated drone scanning delivers more than better documentation—it enables better building.

“As a concrete contractor, I believe the future of our industry lies in telepresence construction, enabling us to secure jobs farther from our home office. With SkyMul’s drone scans, delivering ¼-inch accuracy for as-builts and archival, it’s a game changer.” —David Venegas, owner of VEMAC Concrete

VEMAC, a long-standing El Paso contractor, blends decades of industry expertise with a forward-leaning, technology-driven strategy to maintain its competitive edge.

Adoption Today, Vision for Tomorrow

The barriers to entry are low. On projects using SkyMul’s system, contractors have already begun integrating daily drone scans into site routines—proving that adoption, with a certified pilot, can start today and deliver immediate benefits. Flights are fast, cost-effective, and yield a level of precision and documentation that was once impractical to achieve at this frequency.

Looking ahead, drone-in-a-box technology offers the promise of continuous site awareness, starting each day with the most current as-built data and continuing throughout the day. In the tilt-up sector, where precision drives both speed and cost control, daily aerial QC isn’t the future—it’s the new standard.

Be the first to comment