Collective Position on Specification of Air-Entrainment in Concrete for Tilt-Up Panel Construction

Español | Español | Translation Sponsored by TCA

The position of the Tilt-Up Concrete Association is as follows:

The concrete specified for tilt-up panel construction shall be considered exposure category F0 and not subject to freezing and thawing while in a saturated state, therefore not requiring air-entrainment or a specified minimum air content unless in a horizontal position or when unprotected surfaces are exposed to direct soil contact above a frost line.

Images by Matthew McFarland, m studio west

The concrete surfaces of tilt-up concrete panels in a vertical orientation do not accumulate snow or ice, and do not achieve a saturated state when exposed to moisture sufficient for durability concerns at freezing temperatures. Where vertical surfaces of tilt-up panels are in direct contact with soil conditions with higher moisture content above a frost line, potential saturation of the exterior is a risk and surfaces should be protected with a suitable dampproofing or waterproofing coating.

ACI 318 (Building Code Requirements for Structural Concrete and Commentary) provides that concrete structures must be designed with a concrete mixture that is both sufficient to resist the natural forces to which it will be exposed and appropriate to the nature of the anticipated performance of that exposure condition. In commentary R19.2.1, ACI 318–19 states the following:

Requirements for concrete mixtures are based on the philosophy that concrete should provide both adequate strength and durability. The Code defines a minimum value of f’c for structural concrete. There is no limit on the maximum value of f’c except as required by specific Code provisions.

The durability requirements prescribed in Table 19.3.2.1 are to be satisfied in addition to meeting the minimum f’c of 19.2.1. Under some circumstances, durability requirements may dictate a higher f’c than that required for structural purposes.

Tilt-up concrete panels are vertically oriented slabs of concrete with limited exposure to conditions of saturation. Furthermore, since these wall panels are primarily vertical and located above grade conditions, they have virtually zero exposure to conditions of deicing salts. Therefore, the Tilt-Up Concrete Association believes that the use of air-entraining admixtures is not required to protect the surface of the panels from delamination due to freezing and thawing cycles during saturated conditions.

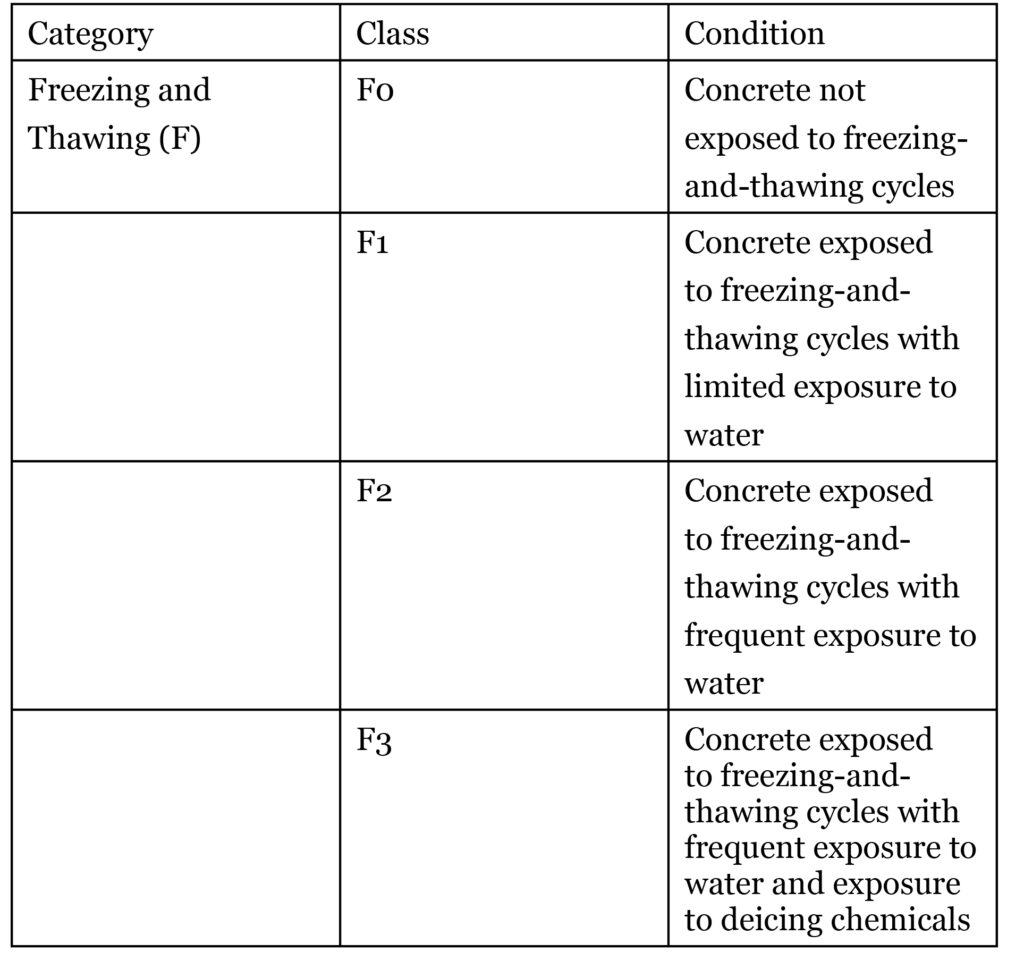

ACI 318 19.3.1.1 requires the licensed design professional to assign the exposure classes in accordance with the severity of the anticipated exposure based on the category for such exposure. Exposure Category F is for Freeze/Thaw Cycling and is described by class as presented in Table 19.3.1.1 below.

Table 19.3.1.1 – Exposure Categories and Classes (Partial)

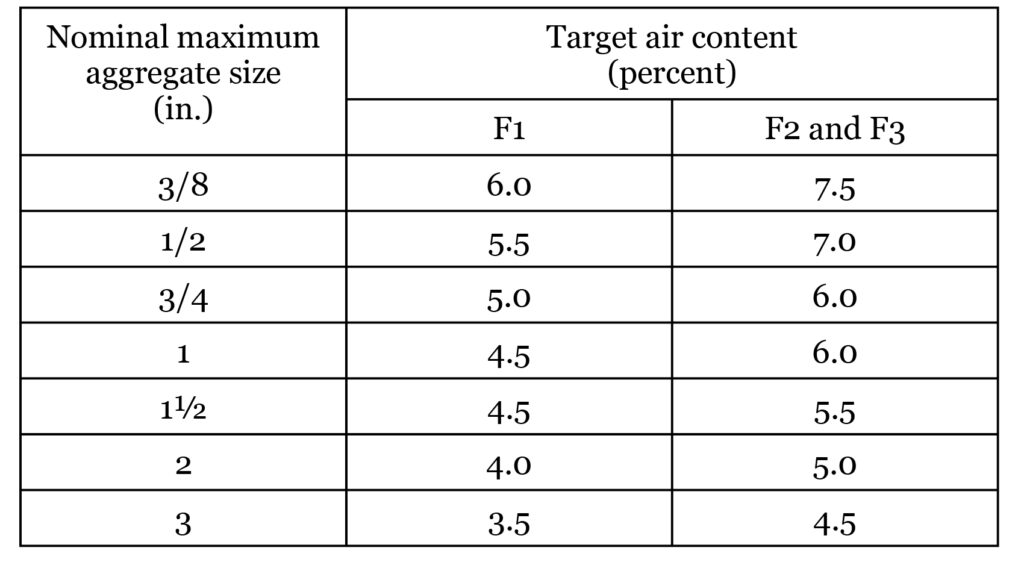

Furthermore, ACI 318 presents in 19.3.2 the requirements for concrete mixtures. Table 19.3.1.2 applies the four classes for Category F to the minimum concrete mixture requirements. This includes air-entrainment requirements for Classes F1, F2 and F3, as described in the commentary R19.3.1.2, reference to Table 19.3.3.1.

Table 19.3.3.1 – Exposure Categories and Classes (Partial)

In accordance with these Code provisions, normal weight and lightweight concrete exposed to freezing-and-thawing cycles or deicing chemicals shall be air-entrained with air content indicated based on the maximum aggregate size. Normal tilt-up construction uses aggregate sizes in the ½ inch to 1 inch range—therefore, a maximum total air content of 4.5% to 5.5% is allowable. Naturally occurring air content, also known as “entrapped air,” is most often estimated between 2% and 3% of a mixture.

While the exposure conditions for tilt-up construction do vary, tilt-up panels are primarily oriented vertically and left exposed to ambient air instead of adjacent to saturated soils. Therefore, there is no condition above grade where the concrete would be subjected to the severe exposure condition.

A large percentage of projects are designed to have the panels coated with a paint system, providing further protection from direct moisture saturation. Elastomeric paint systems are one option that provides a water barrier system of nearly the same measure of water vapor penetration resistance that is found in a below-grade waterproofing application. These paint systems remove the concrete walls from any consideration for exposure and eliminate the need for added air content through entrainment.

Although it is common for designers to consider protecting the concrete from all possible exposure conditions to maintain long-term performance, the history of tilt-up construction is evidence that such measures are unnecessary and may create conditions of risk for surface problems while finishing air-entrained concrete.

There are conditions where air-entrainment may benefit the concrete mix for a project when a specific finish is desired. The incorporation of a forced air bubble structure (AEAs) into a concrete mixture can reduce segregation and significantly reduce bleeding, and may result in a more uniform distribution of aggregate. The latter feature is of particular importance in architectural concrete finishes involving exposed aggregates.

However, considering the use of AEAs must be balanced with recognizing that, for each percentage of air, 2% to 6% of the mix design strength is lost due to the density of the concrete decreasing. Tilt-up construction is a method that relies heavily on the early-age strength of the concrete for sufficient performance of the shear capacity of the concrete around lifting devices, the flexural capacity of the panel as a beam, and the in-place strength of the panel to resist bidirectional wind loads supported solely by braces. The flexural strength of concrete is estimated at only 10% of the compressive strength. A 2% to 6% reduction of mix design strength, at these early ages, significantly changes the means-and-methods design capacity for the performance the contractor needs.

Another factor to consider in the use of AEAs is the ability to finish the surface of tilt-up panels effectively. Contractors will confirm that, for the most part, the use of entrained air makes the concrete sticky or harder to finish. While slight percentages may improve workability, the higher percentages identified as minimum requirements in Table 19.3.31—generally associated with protection against moderate to severe exposure—results in a dramatic change in the surface characteristics of the concrete and a delay in finishing. Therefore, a broom finish is recommended when using an AEA because a trowel finish can cause issues of surface weakness, like delamination.

Presently, ACI 551.2R (Design Guide for Tilt-Up Concrete Panels) provides the following related to entrained air:

Entrained air for resistance to freezing and thawing may not be required because exposed surfaces are primarily vertical and protected with a paint or sealer. Air entrainment reduces strength and, therefore, increases the potential for flexural cracking during lifting. Where saturated conditions are anticipated at the base or parapet of the panel, air entrainment should be considered. Local experience in the performance of concrete without air entrainment should be investigated. In summary, the following concrete specifications are recommended:

28-day compressive strength ……………….4000 psi (27.5 MPa)

28-day flexural strength ……………………….700 psi (4.8 MPa)

Maximum size aggregate ……………………………1 in. (25 mm)

The Tilt-Up Concrete Association recommends working closely with a mix-design specialist associated with the company to provide the concrete for the project. It is critical to ensure the mixture is adequate for the application.

TCA offers this position statement on the assignment of exposure category and class to tilt-up panel construction by licensed design professionals, as approved by the board of directors. This document reinforces what the general building and concrete codes specify, and relates these requirements to the application based on experience and performance.

Want to Know More?

Contact TCA’s Manager for Regulatory and Technical Affairs, James Baty, at 319-895-6911 or via email at jbaty@tilt-up.org.

The mission of the Tilt-Up Concrete Association is to expand and improve the use of tilt-up as the preferred building system by providing education and resources that enhance quality and performance. More information can be found at the Association’s website (www.tilt-up.org), including member-only access to TCA’s Cyber Roundtable for research and area-of-interest discussions.